CNC Vertical Machining Center YMC Series

Features

This series of vertical integrated processing machines, advanced design concepts, solid mechanical structure, stability, smoothness, and movement combine to reflect high-precision, high-speed excellent performance, and high-capacity models. Suitable for high precision mold industry and precision metal processing industry.

The bed and herringbone column are made of densely baked castings with ribs. This casting has excellent stability and good shock absorption characteristics even under heavy cutting conditions. The worktable is fully supported by the integral saddle without any suspension. The four-guide rail design of the base ensures long-term rigidity and accuracy. The guide rails undergo induction hardening heat treatment and precision grinding. The plastic guide rails plus strong lubrication reduce surface friction and reduce wear.

Adopt well-known brands of high rigidity and precision linear slide rails, the process technology is like manufacturing bearings, with zero clearance and all-round bearing characteristics. Linear slide has low consumption, high precision and fast moving speed, up to 48m/min.

The servo motor is directly connected to the screw rod through a rigid coupling without backlash, which can ensure the processing accuracy. Even if it is a very complex task, it can also process sharp cut angles, which ensures the processing accuracy.

High-speed, high-precision, high-rigidity; excellent models for heavy-duty and heavy-cut, Y/Z axis adopts 45° roller linear guide, and Z-axis adopts heavy-duty six-slider design.

Each machine tool has undergone heavy-duty full-tool testing to ensure that even heavy-duty tools can run smoothly and change tools.

Technical Specifications

|

Specifications |

UNIT |

YMC-855 |

YMC-1160 |

YMC-1270 |

YMC-1370 |

YMC-1580 |

YMC-1680 |

YMC-1890 |

|

X/Y/Z-axis Travel |

mm |

800/550/550 |

1100/600/600 |

1300/700/700 |

1300/700/700 |

1500/800/700 |

1600/800/700 |

1800/900/800 |

|

Worktable size |

mm |

550×1000 5-18×90 |

600×1200 5-18×100 |

700×1400 5-18×115 |

700×1400 5-18×110 |

800×1700 7-22×110 |

800×1700 7-22×110 |

900×2000 7-22×125 |

|

Max. load of worktable |

kg |

600 |

800 |

1000 |

1200 |

1500 |

1700 |

2000 |

|

Distance from spindle nose to worktable |

mm |

130-680 |

130-680 |

130-680 |

130-680 |

130-680 |

130-680 |

130-680 |

|

Distance between two columns |

mm

|

/ |

/ |

/ |

/ |

/ |

/ |

/ |

|

Spindle Tapper |

|

BT40 |

BT40 |

BT40 |

BT40 |

BT40 |

BT40 |

BT40 |

|

Spindle speed |

rpm |

8000/12000 |

8000/12000 |

8000/12000 |

8000/12000 |

8000/12000 |

8000/12000 |

8000/12000 |

|

Spindle power |

kw |

5.5/7.5 |

5.5/7.5 |

5.5/7.5 |

5.5/7.5 |

5.5/7.5 |

5.5/7.5 |

5.5/7.5 |

|

G00 Rapid feed X/Y/Z-axis |

mm/min 48000/48000/ |

mm/min 48000/48000/ |

mm/min 48000/48000/ |

mm/min 48000/48000/ |

mm/min 48000/48000/ |

mm/min 48000/48000/ |

mm/min 48000/48000/ |

mm/min 48000/48000/ |

|

G01 Cutting feed |

mm/min |

1-8000 |

1-8000 |

1-8000 |

1-8000 |

1-8000 |

1-8000 |

1-8000 |

|

Machine Weight |

kg |

5000 |

5000 |

5000 |

5000 |

5000 |

5000 |

5000 |

|

Cutting fluid capacity |

liter |

200 |

200 |

200 |

200 |

200 |

200 |

200 |

|

Lubricating oil tank capacity |

liter |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

|

Electricity demand |

kVA |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Air pressure requirements |

kg/cm² |

5-8 |

5-8 |

5-8 |

5-8 |

5-8 |

5-8 |

5-8 |

|

Tool magazine type |

|

Disc type |

Disc type |

Disc type |

Disc type |

Disc type |

Disc type |

Disc type |

|

Tool magazine specifications |

|

BT40 |

BT40 |

BT40 |

BT40 |

BT40 |

BT40 |

BT40 |

|

Tool magazine capacity |

|

24(30) |

24(30) |

24(30) |

24(30) |

24(30) |

24(30) |

24(30) |

|

Maximum tool size (diameter / length) |

mm |

φ80/260 |

φ80/260 |

φ80/260 |

φ120/350 |

φ120/350 |

φ120/350 |

φ120/350 |

|

Maximum tool weight |

kg |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

|

Positioning accuracy |

mm |

0.008/300 |

0.008/300 |

0.008/300 |

0.008/300 |

0.008/300 |

0.008/300 |

0.008/300 |

|

Repeat positioning accuracy |

mm |

0.005/300 |

0.005/300 |

0.005/300 |

0.005/300 |

0.005/300 |

0.005/300 |

0.005/300 |

|

Machine Overal Size |

mm |

2700*2600*2850 |

3100*2700*2900 |

|

3700*3000*3150 |

4100*3400*3200 |

|

5400*3900*3700 |

Configuration Diagram

(1)FANUC System

The panel is intuitive and precise surface, easy to operate.

(2)Linear Guide

Linear guides have zero-gap uniform surface texture for higher positioning accuracy.

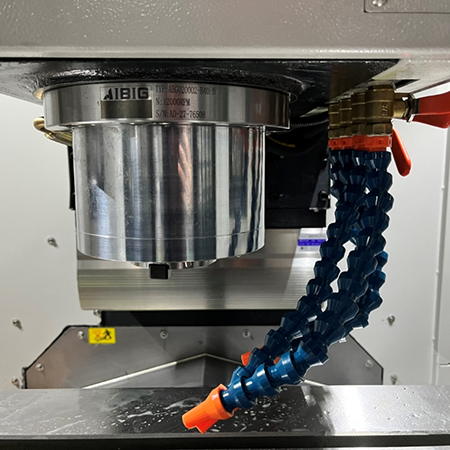

(3)Spindle

A2-6/A2-8/A2-11/A2-15 spindles can be selected according to different machine models.

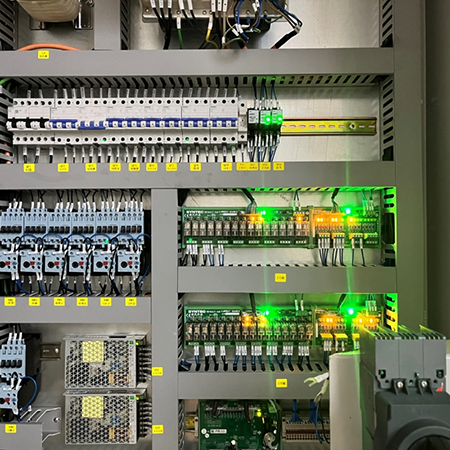

(4)Electrical Cabinet

Control various movements of the machine and monitor its operating status

(5)Tool Magazine

Significantly shortens processing times and reduces tool change times.