CNC horizontal 5-axis NHM-50-P

Introduction of 5-axis machine

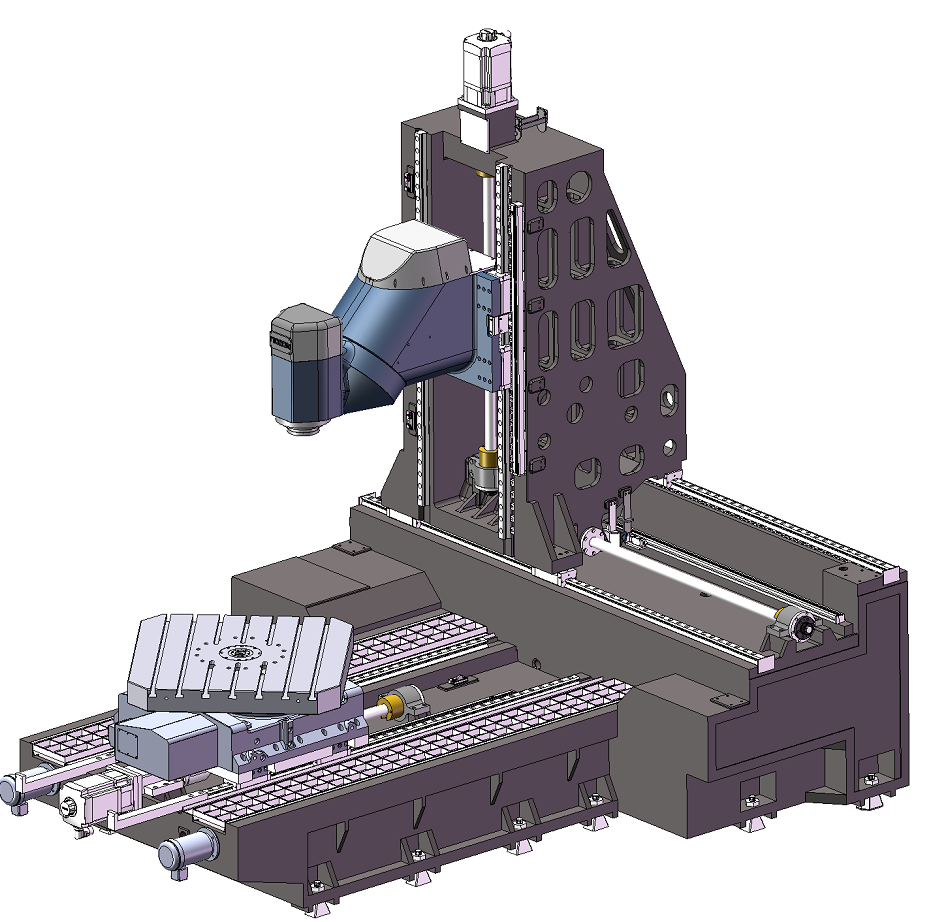

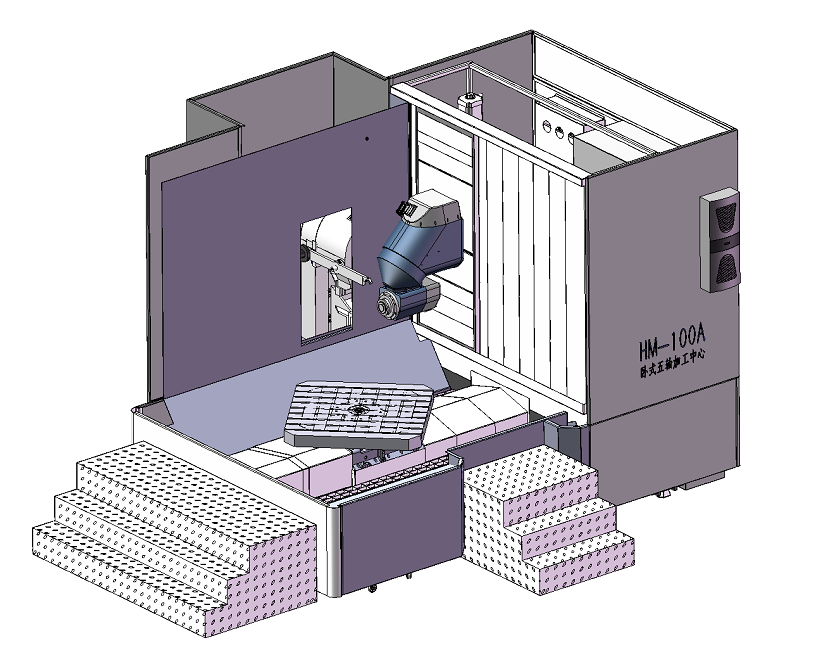

The NHM model is a vertical-to-horizontal conversion horizontal five-axis machining center. The standard configuration of the machine tool is SIEMENS 840D sl CNC system, and the high probability of Siemens servo motor direct drive is adopted, which makes the machine tool have the characteristics of high positioning accuracy, fast response speed, and five-axis linkage processing. At the same time, the machine tool is equipped with an automatic tool changing device, which fully reflects the efficient and automatic processing.

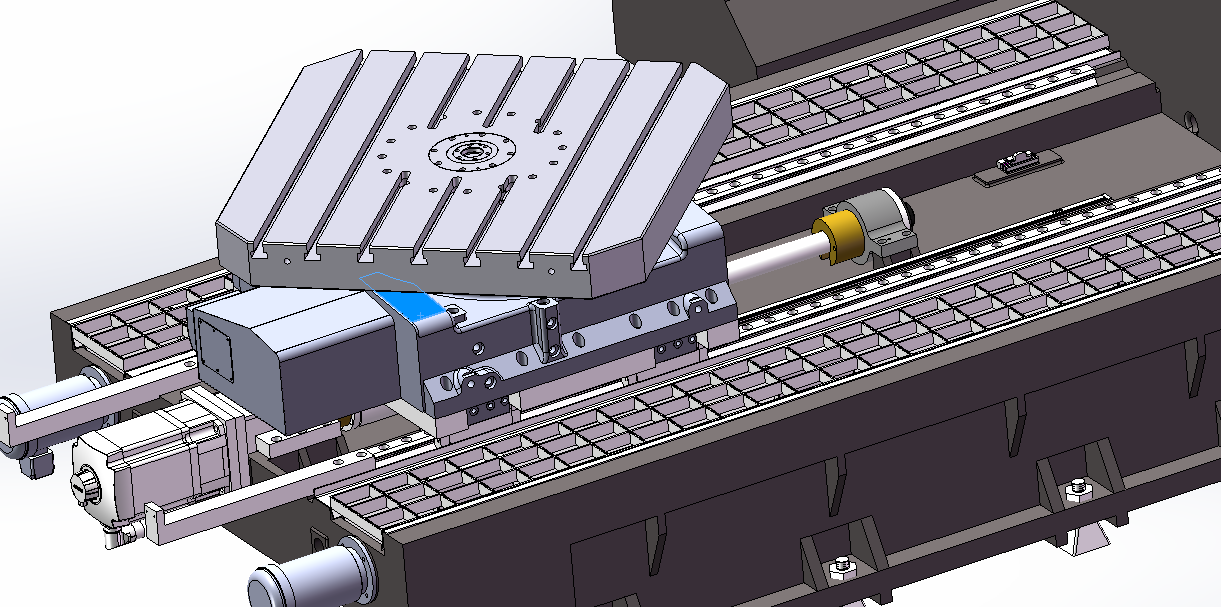

The machine tool moves left and right through the slide plate (X axis), the worktable moves back and forth (Z axis), the headstock moves up and down (Y axis), the table rotates (C axis) and the milling head rotates (B axis), which realizes the five-axis linkage. sports. The whole machine is composed of bed, column, sliding plate, rotary table, milling head, pneumatic system, automatic lubrication system, chip removal cooling system, electrical system and fully enclosed protection system.

The machine tool is equipped with an electric spindle as standard, with the function of central water outlet, which can realize the automatic loosening and broaching of the spindle. The three linear feed axes of the machine tool, X, Y, and Z, use servo motors to directly drive the ball screw to rotate through the coupling. The transmission system has high motion precision and transmission rigidity.

The main purchased parts of the machine tool are all purchased from first-class brands, with water coolers, chip conveyors and chip trucks as standard

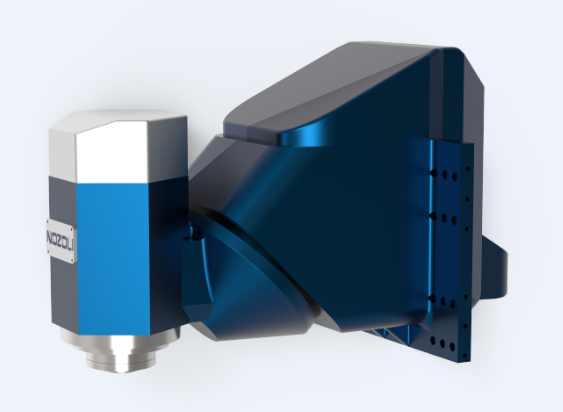

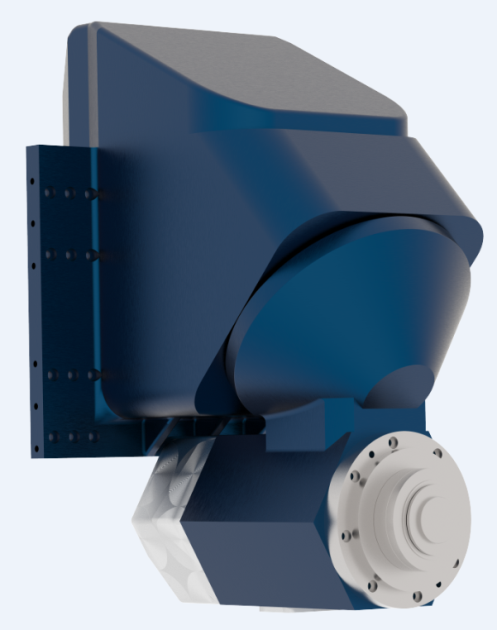

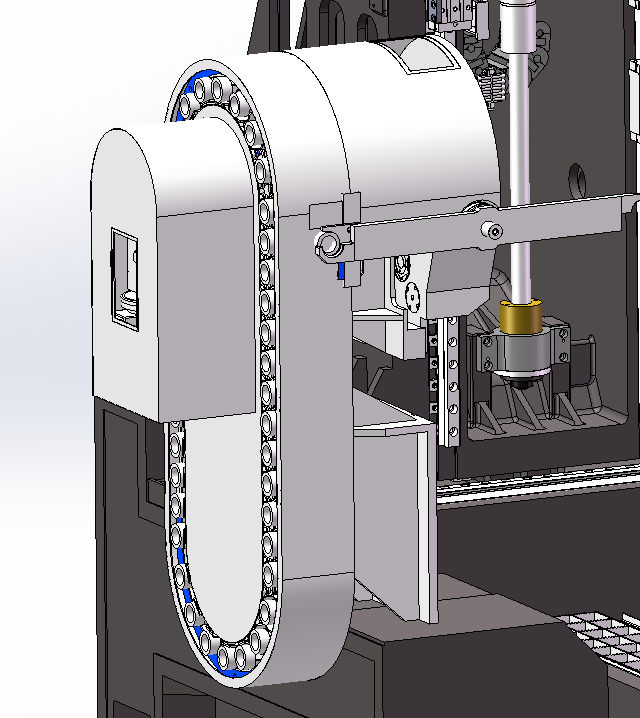

The vertical and horizontal heads can be rotated in two mutually perpendicular rotating planes.

It realizes vertical-to-horizontal conversion and multi-face machining, and solves the multi-faceted, multi-edge and multi-slot milling of various angles in one clamping of the workpiece.

High-performance electric spindle, short machining time, high cutting efficiency, long tool, high machining accuracy

Compact design, high-sensitivity passive clamping system, high-stable brake, and high-precision machining

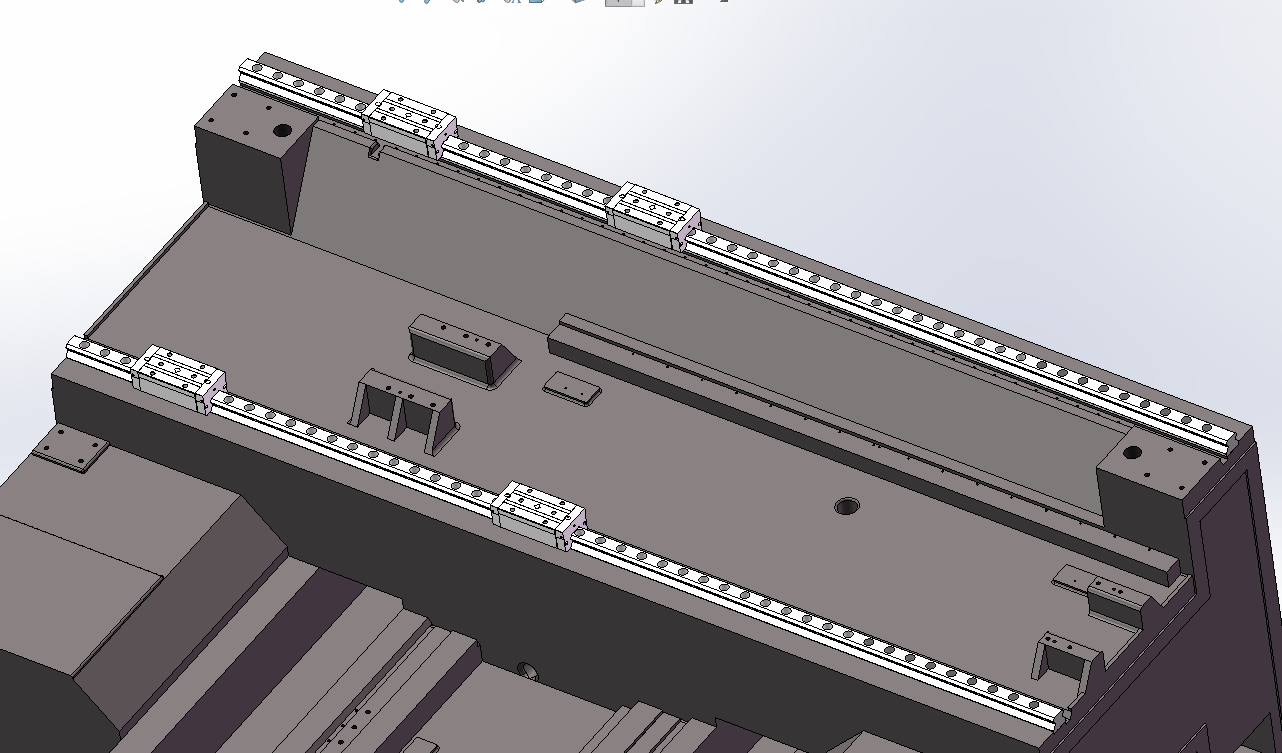

The NHM model is a vertical-horizontal conversion type five-axis linkage machining center. The three-axis adopts high-precision, high-load, high-speed, high-rigidity, low-noise linear roller guides, which move smoothly without crawling and provide perfect feed performance.

High-precision positioning and clamping mechanism, the use of high-performance positioning and clamping mechanism can ensure the rigid clamping and precise positioning of the tray, and the repeated positioning accuracy of the tray can reach 0.003mm.

The bed adopts a T-shaped integral bed, and the shock resistance is improved by 15%. The design layout is an inverted T-shaped structure for the vertical and horizontal beds, and the structure is compact.

Has a larger machining range and higher workpiece load capacity

Modular design, rich expansibility, can be used as a flexible manufacturing system with automatic lines

(1) X guide rail form: the column is equipped with two 55mm heavy-duty roller linear guide rails. It can meet the requirements of high rigidity and strength, and can meet the technical advantages of small friction coefficient, fast moving speed and long service life; lubrication method: oil lubrication; wire gauge brand: Taiwan Shangyin or the same grade brand;

(2) X-axis drive: After the AC servo motor is used to increase and decrease the speed, it drives the 50mm diameter precision ball screw to rotate to achieve left and right feed; Lubrication method: oil lubrication; Screw brand: Taiwan Shangyin or the same grade brand;

(3) Equipped with double high-precision full-closed-loop grating scale; grating scale brand: Spain FAGOR or the same grade brand;

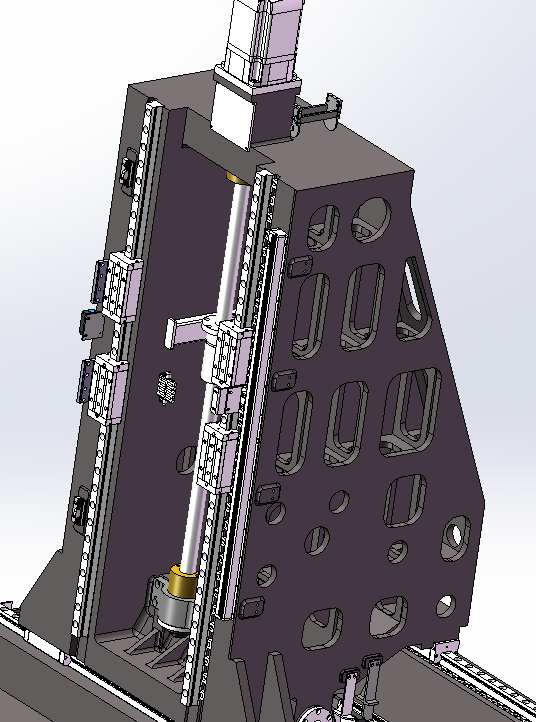

(1) Guide rail form: The Y-axis adopts two 55 heavy-duty roller linear guide rails as the guide and load-bearing track for the vertical and horizontal universal milling head to move up and down. It can meet the technical requirements of high-speed finishing and low-speed heavy cutting. Lubrication method: oil lubrication. Wire gauge brand: Taiwan Shangyin or the same grade brand;

(2) Y-axis transmission: After the AC servo motor is used to increase and decrease the speed, it drives the 50mm diameter precision ball screw to rotate to realize up and down feeding. Lubrication method: oil lubrication. Screw brand: Taiwan Shangyin or the same grade brand;

(3) Equipped with high-precision full-closed-loop grating scale; grating scale brand: Spain FAGOR or the same grade brand;

(4) XY guide rail protection: The overall armor shield is used for protection to prevent foreign objects from entering and contaminating the guide rail. The protective cover has a beautiful appearance and a reasonable structure.

(1) Guide rail form: Z-axis adopts two 55 heavy-duty roller linear guide rails as the guide and load-bearing rail for the table to move; Lubrication method: oil lubrication; Wire gauge brand: Taiwan Shangyin or the same grade brand;

(2) Z-axis transmission: After the AC servo motor is used to raise and lower the speed, it drives the 50mm diameter precision ball screw to rotate to realize the front and rear feeding of the Z-axis; Lubrication method: oil lubrication; Screw brand: Taiwan Shangyin or similar brands ;

(3) Equipped with double high-precision full-closed-loop grating scale; grating scale brand: Spain FAGOR or the same grade brand.

CNC controlloer: Siemens 840Dsl

The CNC system of the machine is a Sinumerik 840 sl from SIEMENS

While meeting the basic configuration of the CNC system, the following special requirements are guaranteed

Minimum control unit: linear axis≤0.001mm, rotary axis≤0.001°

Graphical simulation function

Corner deceleration function

Helical interpolation

Milling function

Master-slave control authorization

With 15-inch screen

With MCP 398C operator panel

Including 72/48 IO board

NX10.3 expansion axis module

DMC20 Hub Module

data collection

Provide relevant information through OPCUA or 485 or upper-level software to realize informatization co-connection with user equipment, including but not limited to:

Equipment operation data (speed, feed force, tool name, tool holder length, spindle force value, program name and version, alarm record, operation panel record, process parameters of coordinate system zero offset, etc.)

Device name, software version, program name and version of the currently running program

Equipment operating status (including but not limited to startup not working, working, shutdown, and fault status), and can provide equipment failure warning, power consumption detection, etc.

PLC running status

Lubrication system; this machine adopts group independent oil supply technology

(1) A set of independent automatic oil supply and lubrication system is adopted for X, Y, Z axis guide rail, lead screw and rack. The screw bearing is grease lubricated.

(2) The main shaft oil and gas lubrication/automatic thin oil lubrication is a timing and quantitative automatic mode, the action is automatically controlled by the numerical control system, and can be detected and alarmed. Lubrication pump brands are optional: SKF oil-air lubrication/Proton or similar brands

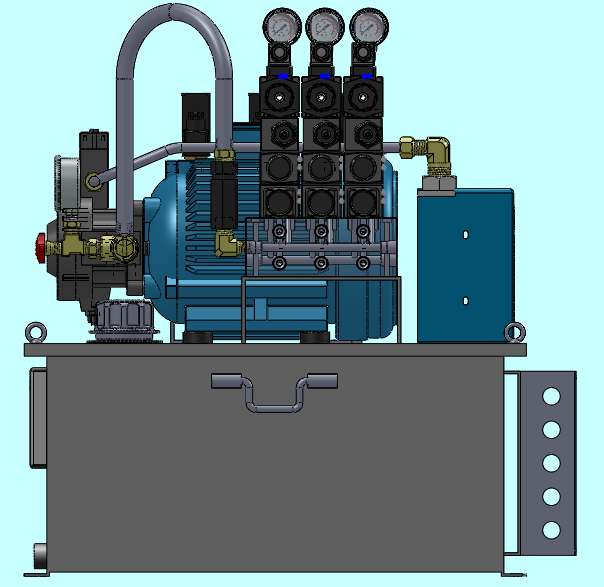

Hydraulic system

(1) This machine tool is equipped with an independent hydraulic system.

(2) The machine tool is equipped with a separate hydraulic pump station, and the hydraulic system is equipped with a number of safety monitoring devices such as oil level alarm, temperature alarm, backflow blockage alarm, and minimum working pressure alarm to ensure that the machine tool works under various safe conditions. , improve the safety protection of operators.

(3) Hydraulic station brand: well-known domestically

Tool magazine chain magazine 40T HSK-A63

Tool magazine brand: Taiwan-funded enterprise Desu/Okada or similar brands

The drainage grooves on both sides and the base are integrally cast, and the leakage prevention effect is good;

The spiral chip conveyors on both sides of the processing area quickly transport the iron chips generated by high-speed processing to the lifting chip conveyor, reducing the thermal deformation and deformation of the machine tool, and ensuring the accuracy and stability of the machine tool;

Technical Information

|

MODEL |

NHM-50-P |

|

X-axis travel (the table moves back and forth) |

700 |

|

Y-axis travel (the carriage moves left and right) |

900 |

|

Z-axis travel (ram moves up and down) |

780 |

|

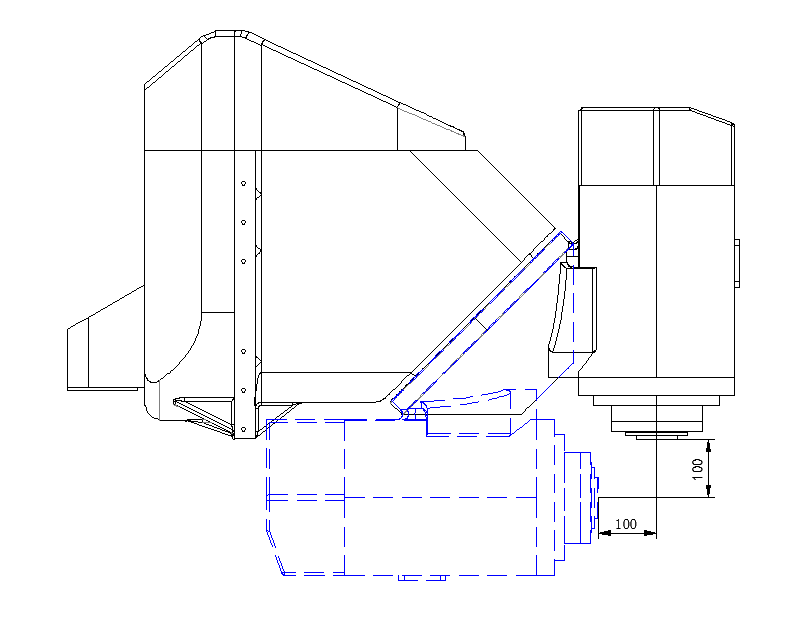

Distance from spindle end face to work table |

100-1350 |

|

working desk size |

500X500 |

|

weight capacity |

1 |

|

Spindle maximum speed |

15000 |

|

Main motor power (rated) |

15 |

|

Maximum torque (rated) |

72 |

|

Spindle taper |

HSK-A63 |

|

maximum torque |

2040 |

|

maximum clamping torque |

1320 |

|

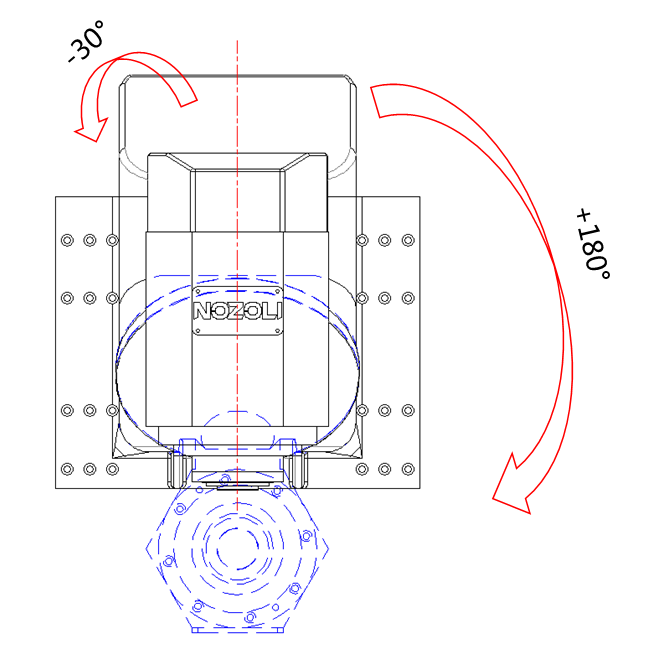

Swing angle |

±180°--30° |

|

positioning accuracy |

±5” |

|

Repeatability |

±3.5” |

|

positioning accuracy |

±10” |

|

Repeatability |

±6” |

|

X, Y, Z rapid traverse speed |

24/24/24 |

|

X, Y, Z positioning accuracy |

≤0.008 |

|

X, Y, Z repeat positioning accuracy |

≤0.005 |

Standard configuration

|

Siemens 840Dsl CNC system |

Germany |

|

X, Y, Z feed servo motors |

Siemens Germany |

|

XYZ Servo Drive |

Siemens Germany |

|

AC Servo Spindle Motor |

Siemens Germany |

|

Five-axis five-link head |

Shanghai |

|

Ball screw |

HIWIN or equivalent brand |

|

Linear Roller Guide |

HIWIN or equivalent brand |

|

Each shaft screw bearing |

Japan NSK or equivalent brand |

|

Coupling |

Taiwan or equivalent brand |

|

Spiral cutter |

Shanghai |

|

Machine tool guide rail protection |

Shanghai |

|

Oil pump and centralized lubrication system |

Proton or SKF or equivalent |

|

Proximity switch, intermediate relay |

Omron/Schneider or equivalent |

|

hand pulse generator |

System supplier designated manufacturer/or equivalent brand |

|

Spindle |

INNA or equivalent |

|

Machine tool large casting |

Shanghai |

|

Machine tool sheet metal outer protection |

Shanghai |

|

Machine tool anchor bolts, horn complete set |

Shanghai |

|

Hydraulic system |

famous in China |

|

Work Lights and Warning Lights |

famous in China |

|

Spindle ram balance mechanism |

famous in China |

|

Spindle cooling system and water supply system |

famous in China |

|

Common maintenance tools |

famous in China |

|

Mechanical Instruction Manual |

|

|

Electrical Instruction Manual |

|

|

Certification |

|

|

Packing List |

|

|

Electrical schematic |

|

|

System Operation Manual |

|

|

System Maintenance Manual |

|

|

System parameter manual |

|

|

System factory parameter table |

|

|

Foundation drawing |

Provided after the contract takes effect |

|

Control box temperature regulator manual |

|

Thanks for your attention!