CNC Drilling and Tapping Machining Center CT Series

Features

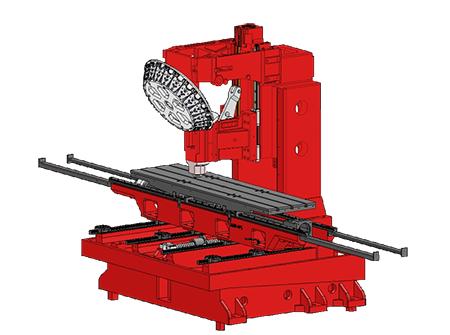

The high-speed, high-performance, high-precision drilling, milling and tapping machining center CT1600 has the characteristics of high rigidity, high precision and high-efficiency processing. The column adopts a herringbone design and a large span, which can greatly enhance the bending and torsional strength of the column; the workbench adopts a reasonable slider span to make the workbench evenly stressed; the bed adopts a trapezoidal cross-section to lower the center of gravity and improve torsional strength; the whole machine adopts the best structural design to provide the best overall stability.

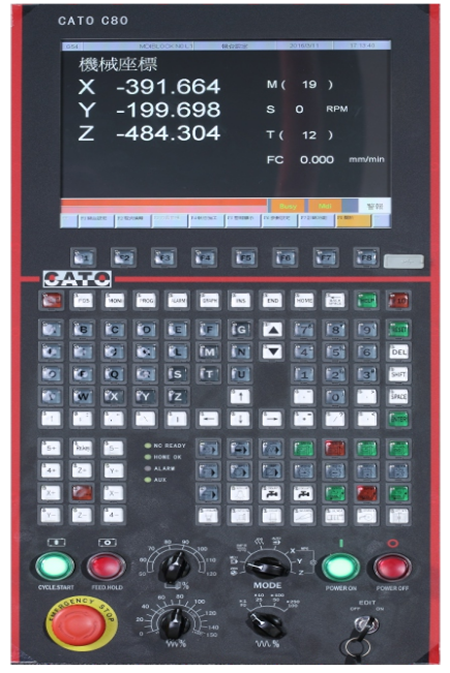

Using CATO's latest C80 Plus system, 15-inch ultra-large LCD display, tool trajectory dynamic graphic display, intelligent warning display, self-diagnosis and other functions make the use and maintenance of the machine tool more convenient and quick; the high-speed bus communication method greatly improves the data processing capacity and control performance of the CNC system, the program storage capacity is increased to 4G, and the pre-reading capacity is increased to 3000 lines/second, which facilitates the fast and efficient transmission and online processing of large-capacity programs.

Technical Specifications

|

Item |

CT500 |

CT700 |

CT1000 |

CT1500 |

|

|

Travel |

X-axis travel |

500mm |

700mm |

1000mm |

1570mm |

|

Y-axis travel |

400mm |

400mm |

600mm |

400mm |

|

|

Z-axis travel |

330mm |

330mm |

300mm |

330mm |

|

|

Distance from spindle end to worktable center |

150-480mm |

150-480mm |

200-500mm |

150-480mm |

|

|

Worktable |

Table size |

650×400mm |

850×400mm |

1100×500mm |

1700×420mm |

|

Max.load of worktable |

300kg |

350kg |

500kg |

300kg |

|

|

Spindle |

Spindle taper hole |

BT30 |

|||

|

Max.spindle speed |

24000rpm |

12000rpm |

12000rpm |

12000rpm |

|

|

Spindle motor power (continuous/S360%) |

8.2/12 kW |

||||

|

Spindle motor torque (continuous/S360%) |

26/38 N.m |

||||

|

Feed rate |

X/Y/Z axis rapid speed |

60/60/60mm |

60/60/60mm |

48/48/48mm |

48/48/48mm |

|

Cutting feed |

50-30000mm/min |

||||

|

Tool magazine |

Number of installed tools |

21T |

|||

|

Max.tool diameter/length |

80/250mm |

||||

|

Max.tool weight |

3kg |

||||

|

Total weight of tool |

≤33kg |

||||

|

Tool change time (tool to tool) |

1.2-1.4sec. |

||||

|

Accuracy |

positioning accuracy |

±0.005/300mm |

|||

|

Repeatability |

±0.003mm |

||||

|

Power |

Power capacity |

16.25 KVA |

12.5 KVA |

||

|

Air pressure demand |

≥6 kg/cm² |

||||

|

Air source flow |

≥0.5mm³/min |

||||

|

Machine size |

Machine weight |

2.7t |

2.9 t |

4.8t |

5.5t |

|

Mechanical dimensions (Length × Width × Height) |

1589×2322×2304mm |

1988×2322×2304mm |

2653×2635×3059mm |

4350×2655×2571mm |

|

Configuration Introduction

(1)CATO C80 System

The world's first-class industrial control system, the first to use Windows system; high speed and high precision, and up to 16-axis control; standard 256MB hard disk file storage. FANUC Oi-MF System can be selected according to needs.

(2)Spindle

The high acceleration and deceleration spindle motor enables the spindle to start and stop in a short time, and the tool can be replaced without stopping the Z axis.

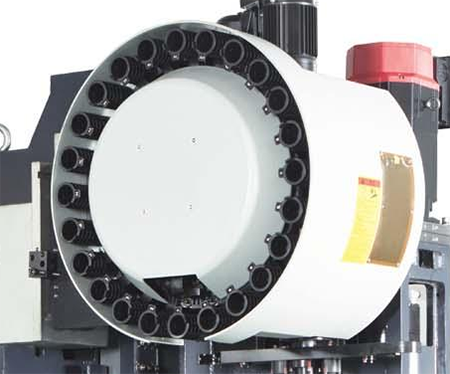

(3)Tool Magazine

The non-stop splitting method uses a new type of rotary structure, which greatly shortens the tool exchange time. The servo motor control makes the tool magazine movement smoother.

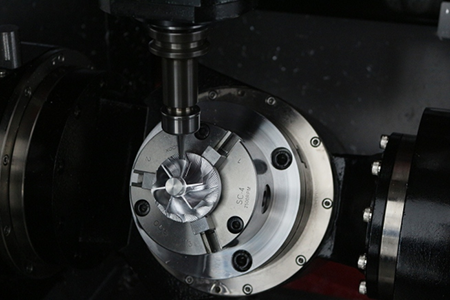

(4)Rotary table

2000rpm high-efficiency rotary table to achieve high-efficiency and high-precision turning.

(5)Bed and column

The optimization of the configuration of the improved structural shape has increased the rigidity of the machine. The optimization of the shape and configuration of the bed and column are the most suitable shapes after CAE analysis, reflecting the stable cutting ability that cannot be shown by the spindle speed.

Processing Cases

Automotive Industry

New energy battery housing

Cylinder block

Connecting rod

Engine housing

EPS housing

Shock absorber

Gearbox housing

Cam Phaser

Transmission bearings

Clutch housing

Cylinder head

Rear cylinder

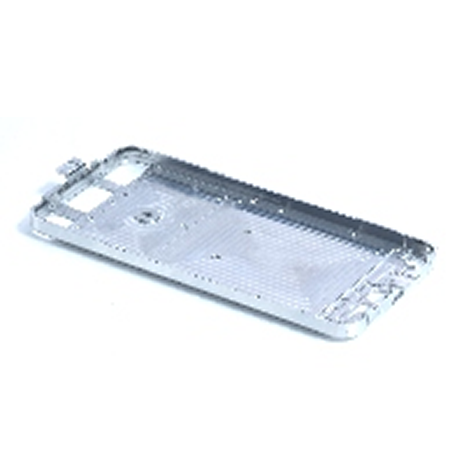

3C Industry

Mobile phone

Wearable Watches

Laptop

Communication cavity

Military Industry

Impeller

Aero seat frame

Door closers housing

Rear wheel mount