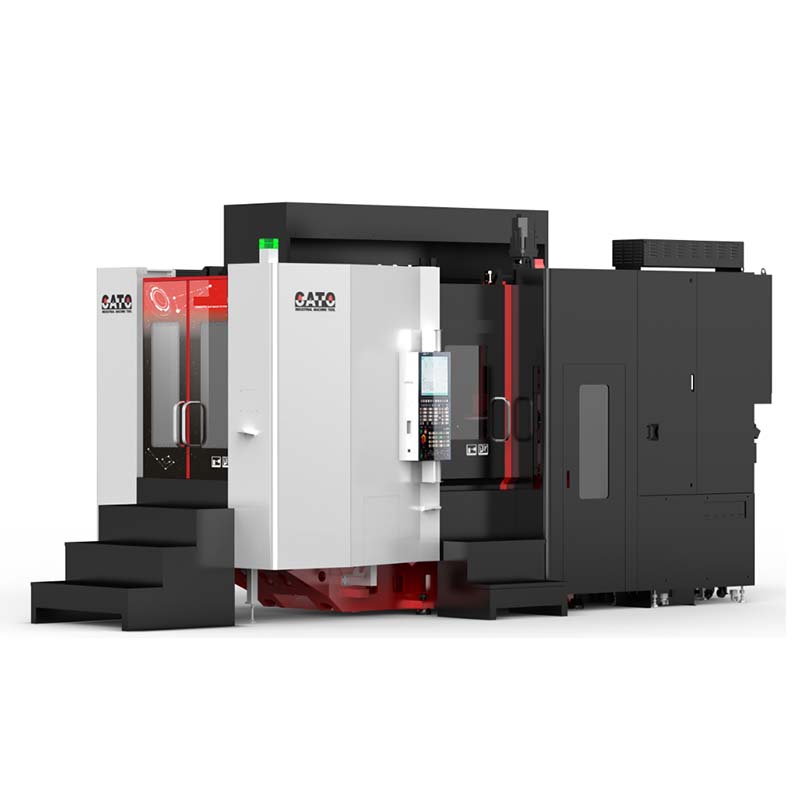

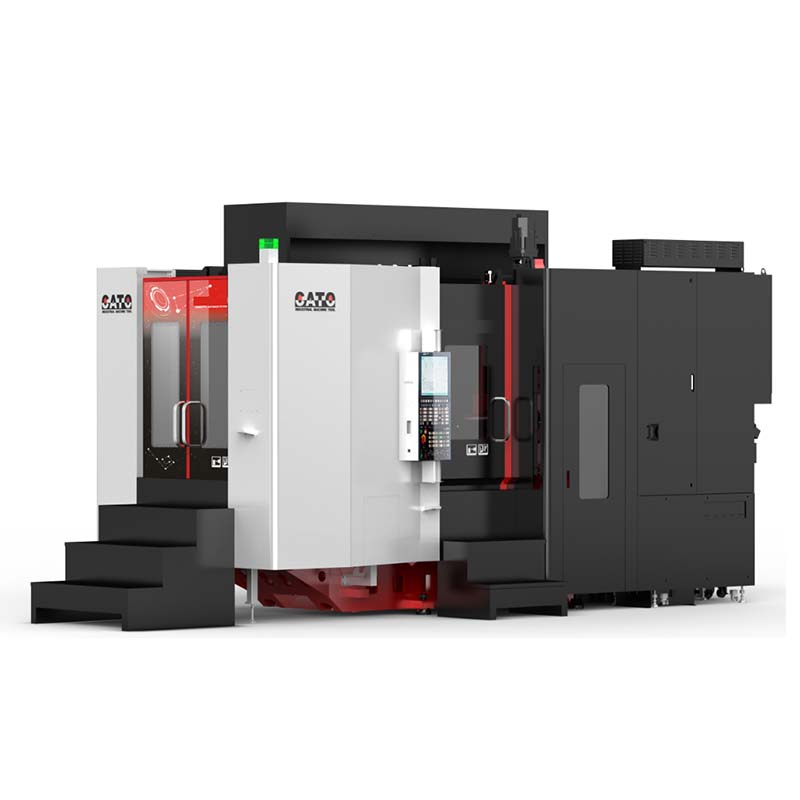

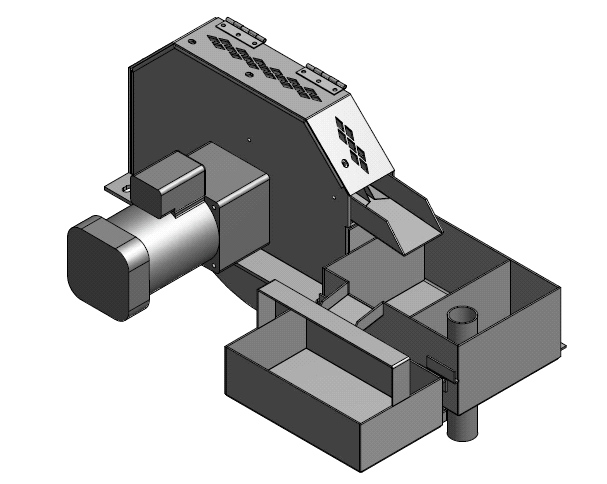

5-axis CNC Horizontal Machining Center With Two Pallets CP800

1.Features

The high-speed, high-performance and precision horizontal five-axis machining center CP800T2 developed by CATO Company has the characteristics of high rigidity, high precision and high efficiency machining. The one-piece base is adopted, and the positive T structure design of the base's high and low rails ensures the high rigidity of the machine tool; the whole machine passes the finite element analysis to ensure that the machine tool does not vibrate under high-speed motion, and guarantees the best long-term operation stability of the whole machine.

By adopting high-end technologies such as high-speed spindle technology, high-speed feed technology, high-speed tool change technology, and high-speed CNC system technology, the processing time is greatly shortened, the processing efficiency is improved, and various production needs are met. The three-axis rapid displacement is 60 M/min, and the high-speed and high-torque electric spindle reduces the acceleration and deceleration time of the spindle. These indicators greatly shorten the non-processing time and improve the processing efficiency; the screw/bearing seat/spindle/DD swing head adopts a temperature control system, Guarantee the excellent thermal balance of the equipment, and greatly improve the accuracy and stability of the equipment.

Adopting Siemens 840D system, 19-inch super large LCD display, dynamic graphic display of tool trajectory, intelligent warning display, self-diagnosis and other functions make the use and maintenance of the machine tool more convenient and fast; the high-speed bus communication method greatly improves the data processing of the CNC system The ability and control performance facilitate the fast and efficient transmission and online processing of large-capacity programs.

2.Parameter

|

Item |

Unit |

CP800T2 |

|

|

Travel |

Travel of X/Y/Z axis |

mm |

800 x 800 x 750 |

|

B-axis travel |

° |

-30~120 |

|

|

C-axis travel |

° |

360 |

|

|

Distance from the spindle center to the table top (B-axis 90 degrees horizontal) |

mm |

160~910 |

|

|

Distance from spindle end face to table top (B-axis 0 degree vertical) |

mm |

-83~667 |

|

|

The distance from the end face of the spindle to the center of the worktable (B-axis 90 degrees horizontal) |

mm |

-135~665 |

|

|

Distance from spindle center to table center (B-axis 0° vertical) |

mm |

108~908 |

|

|

Maximum processing range |

mm |

Φ 720 x 910 |

|

|

Feed of 3 axis |

X/Y/Z axis fast move |

m/min |

60/60/60 |

|

Cutting feed rate |

mm/min |

0-24000 |

|

|

Rotary table (C-axis) |

Rotary table |

pcs |

2 |

|

Disc diameter |

mm |

500*500 |

|

|

allowable load |

Kg |

500 |

|

|

maximum rotation speed |

Rpm |

40 |

|

|

Positioning/Repeat Accuracy |

arc.sec |

15 / 10 |

|

|

B-axis |

Maximum rotation speed |

Rpm |

60 |

|

Positioning/Repeat Accuracy |

arc.sec |

8 / 4 |

|

|

Spindle |

Spindle specification (installation diameter/transmission method) |

mm |

190 / Built-in |

|

Spindle taper |

m/min |

A63 |

|

|

Max. Spindle speed |

mm |

18000 |

|

|

Spindle Motor Power |

Kw |

30/35 |

|

|

Spindle Motor Torque |

N.m |

72/85 |

|

|

Tool |

Tool magazine capacity |

|

40 T |

|

Tools change time(T-T) |

s |

7 |

|

|

Maximum tool diameter (Full tool / Adjacent empty tool tool) |

mm |

80/150 |

|

|

Max. Tool length |

mm |

450 |

|

|

Max. Tool weight |

Kg |

8 |

|

|

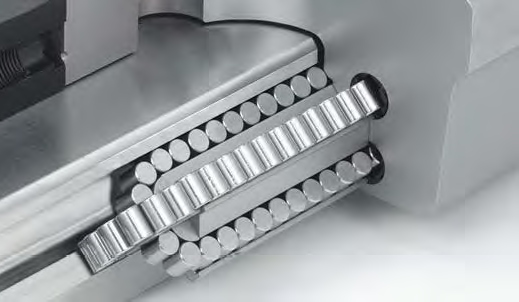

Guide |

X-axis guide (size/number of slides) |

|

45/2 (Roller) |

|

Y-axis guide (size/number of slides) |

|

45/3 (Roller) |

|

|

Z-axis guide (size/number of slides) |

|

45/2 (Roller) |

|

|

Three axis transmission |

X-axis lead screw |

N |

2R 40 x 20 |

|

Y-axis lead screw |

N |

2R 40 x 20 |

|

|

Z-axis lead screw |

N |

2R 40 x 20 |

|

|

Three-axis accuracy |

Positioning accuracy |

mm |

0.005 / 300 |

|

Repeat positioning accuracy |

mm |

0.003 / 300 |

|

|

Lubrication system |

Lubrication unit capacity |

L |

0.7 |

|

Lubrication type |

|

Grease lubrication |

|

|

Others |

Air demand |

Kg/cm2 |

≥ 6 |

|

Air source flow |

mm3/min |

≥ 0.5 |

|

|

Weight |

T |

11 |

|

3.Stand configuration

|

NO. |

Name |

|

1 |

Siemens 840D① Excellent curved surface;②Five-axis milling process package;

③ Five-axis card; ④ Prevent the B-axis from falling; ⑤USB and Ethernet data transmission |

|

2 |

Simultaneous tapping function |

|

3 |

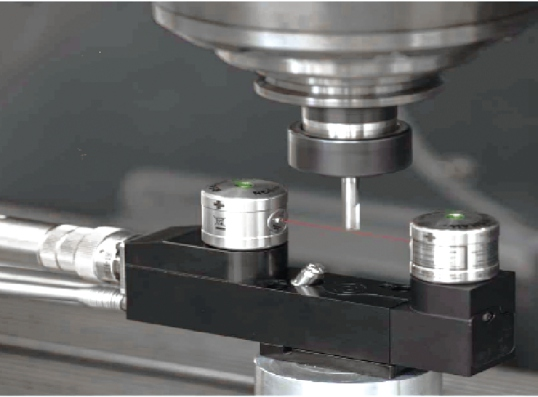

X/Y/Z screw hollow cooling system |

|

4 |

Spindle/B-axis temperature control system |

|

5 |

Spindle overload protection |

|

6 |

APC Double Exchange Workbench |

|

7 |

B/C axis hydraulic brake system |

|

8 |

Fully enclosed sheet metal |

|

9 |

Security Door Lock System |

|

10 |

Tool magazine automatic door |

|

11 |

Automatic grease lubrication system |

|

12 |

LED work light lighting |

|

13 |

Screw cutting on both sides |

|

14 |

Lifting drum scraper removal system |

|

15 |

Surround sprinkler system |

|

16 |

coolant system |

|

17 |

CTS (2MPA) |

|

18 |

Standard tools and tool boxes |

| Standard tools and tool boxes |