China Drive Center Lathe Manufacturers - Center Drive lathe For Coupling – Oturn

China Drive Center Lathe Manufacturers - Center Drive lathe For Coupling – Oturn Detail:

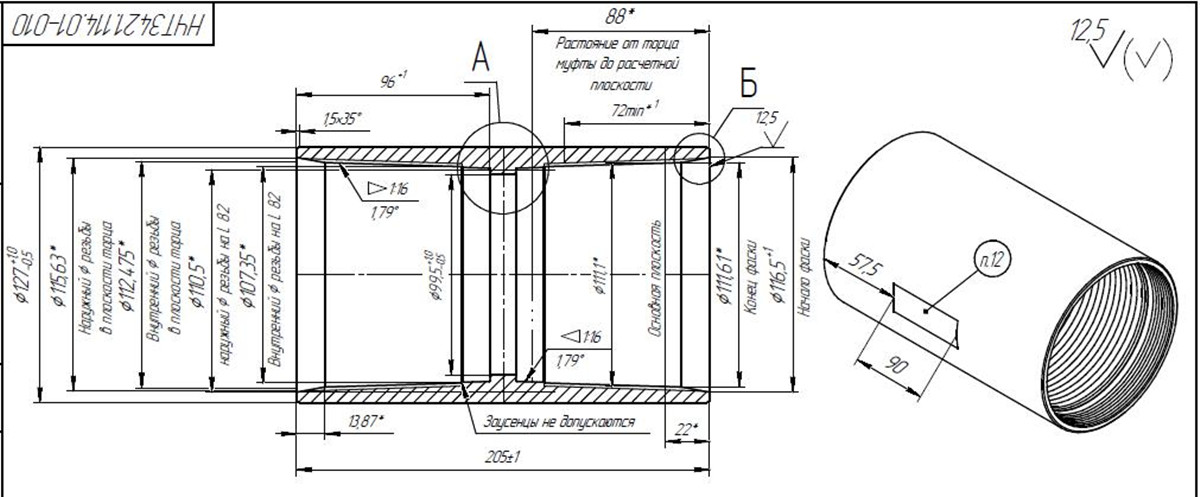

Workpiece Processing Introduction

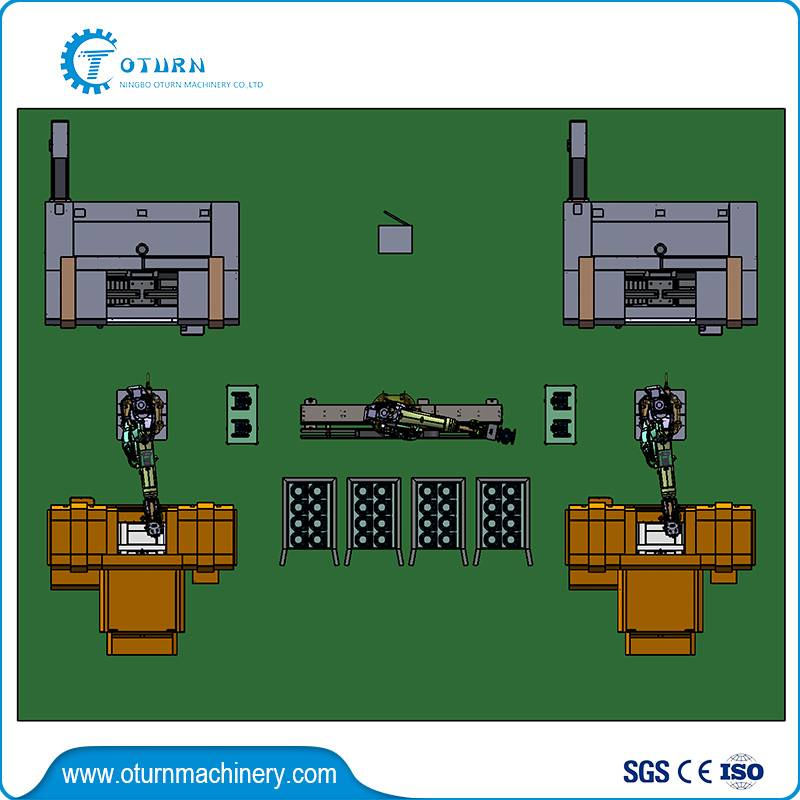

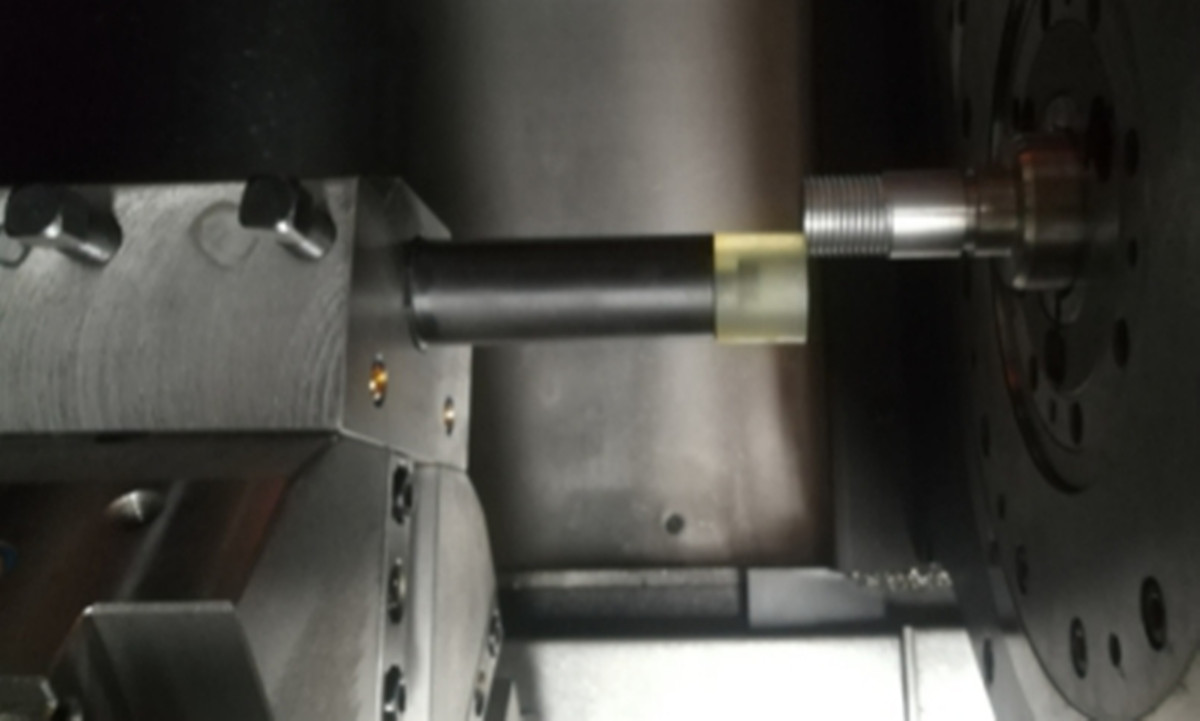

According to the customer’s products drawings,We recommend the SCK205S double-end CNC lathe, which clamps the outer circle of the coupling, and processes both the end surface and the external chamfer, the inner hole and the internal chamfer, and the internal thread (offset buckle) at the same time.Adopting API standards.

|

Part No. |

Max.outer diameter(mm) |

Length(mm) |

Min.inner hole(mm) |

Ladder buckle (in) (API standard) |

Mark |

|

Муфта ОТТМ102-Д |

∮114 |

190 |

∮88.6 |

4 |

|

|

Муфта ОТТГ114-Д |

∮127 |

205 |

∮99.5 |

4-1/2 |

|

|

127 |

∮141.3 |

210 |

∮110 |

5 |

|

|

140 |

∮153.7 |

218 |

∮130 |

5-1/2 |

|

|

146 |

∮166 |

218 |

∮139.35 |

5-3/4 |

|

|

168 |

∮187.7 |

225 |

∮151 |

6-5/8 |

|

|

178 |

∮194.5 |

234 |

∮158 |

7 |

Machine Feature

1.Machine structure and characteristics

■This machine adopts 450inclined bed layout, which has good rigidity and convenient chip removal.

■The headstock integrates the three components of the main shaft system, the fixture, and the clamping cylinder. The structure is compact and reliable, and the fixture is hydraulically clamped.

In order to meet the processing needs

of 4 “-7″ couplings, the solution:

Maximum clamping diameter: φ200mm,

The headstock width is 190mm.

■The clamp is a collet type, and an adjustment jaw is installed on the elastic chuck with a diameter of 2mm. The processing parts are replaced. When changing the clamping diameter, only the adjustment jaw can be replaced.

■According to the processing parts, multiple boring tools are required. To avoid tool interference, the turret is customized. The rotary diameter of the cutter head is large. In order to make the turret more rigid, the center of the turret is selected to be 125mm.

Suggestion: Choose one rough and fine boring cutter for machining end face, chamfer and inner hole;

1 eccentric buckle thread cutter for thread processing.

■The machine tool is equipped with a dual-channel control system. The two tool holders can be linked with the spindle at the same time or separately to complete the simultaneous or sequential processing of both ends of the part.

■Axial positioning of workpieces using positioning posts mounted on the cutter head.

■In order to process the deflection buckle at both ends of the coupling at the same time, minimize the number of passes.

The main motor power in this case is a 18.5 / 22kW wide area servo motor.

Specification

|

Item |

Name |

Unit |

Specification |

Mark |

|

|

Process Range |

Max.swing over the bed |

mm |

Φ550 |

||

|

Max.swing over the slide |

Φ350 |

||||

|

Max.clamping diameter |

Φ200 |

||||

|

Processing length |

Shaft 1000; Tube: 190-400 |

||||

|

Spindle speed |

r/min |

1200 |

|||

|

Headstock |

Headstock width |

mm |

190 |

||

|

Spindle clamping specifications |

Φ114-195(4 inch-7 inch) |

||||

|

Spindle bore |

φ200 |

||||

|

Spindle center to ground height |

1150 |

||||

|

Feed |

Travel |

X1/X2 |

150/150 |

||

|

Z1/Z2 |

480/600 |

||||

|

Work forward |

X/Z |

mm/r |

0.001~6 |

||

|

Fast forward |

X/Z |

m/min |

16 |

||

|

Tool |

Drive method |

Rotary servo, locking hydraulic |

|

||

|

capacity |

station |

Diameter of boring bar |

|

||

|

External tool square size |

mm |

Diameter of boring bar |

|||

|

Diameter of boring bar |

Φ50 |

||||

|

Machine size |

mm |

4900×1850×1900 |

|||

|

Machine weight |

Net weight |

Kg |

6700 |

||

|

Gross weight |

7700 |

||||

Main configurations

(●:standard; ★:Optional)

|

No. |

Name |

Specification |

Qty. |

Brand |

Origin |

Mark |

|

1 |

Control system |

FANUC 0i-TF |

1Set |

FANUC |

Beijing |

★ |

|

2 |

AC servo motor |

X Axis/Z Axis:11Nm |

||||

|

3 |

Servo motor |

18.5/22kW,307Nm |

||||

|

4 |

Spindle bearing |

1Set |

FAG |

Germany |

● |

|

|

5 |

Servo tool holder |

AK36125A-8 |

2Sets |

YTUM |

Yantai |

● |

|

6 |

Tool tray accessories |

Boring tool holderΦ50; External tool holder□32×32 |

2Sets |

YTUM |

Yantai |

★ |

|

7 |

Elastic chuck |

With 2 specifications (based on customer needs) |

1Set |

Self-produced |

Yinchuang |

★ |

|

8 |

Adjusting claw |

With 2 specifications (based on customer needs) |

1Set |

Self-produced |

Yinchuang |

★ |

|

9 |

Ball screw |

X:4008;Z:4010 |

2Sets |

Hiwin |

Taiwan |

● |

|

10 |

Rolling guide |

2Sets |

Hiwin |

Taiwan |

● |

|

|

11 |

Screw bearing |

2Sets |

NSK |

Japan |

● |

|

|

12 |

Centralized lubrication |

1Set |

TTMN |

Yongjia |

● |

|

|

13 |

Cooling pump |

1Set |

Domestic |

China |

● |

|

|

14 |

Hydraulic system |

1Set |

YCCY |

Yinchuang |

● |

|

|

15 |

Electrical components |

ABB, Omron, etc. |

1Set |

Joint venture |

China |

● |

|

16 |

Automatic chip remover |

1Set |

Yufeng |

Yantai |

● |

|

|

17 |

Three-color light |

1Set |

Domestic |

China |

● |

|

|

18 |

Random document |

1Set |

Self-produced |

Yinchuang |

● |

|

|

19 |

Random attachment |

1Set |

Self-produced |

Yinchuang |

● |

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.