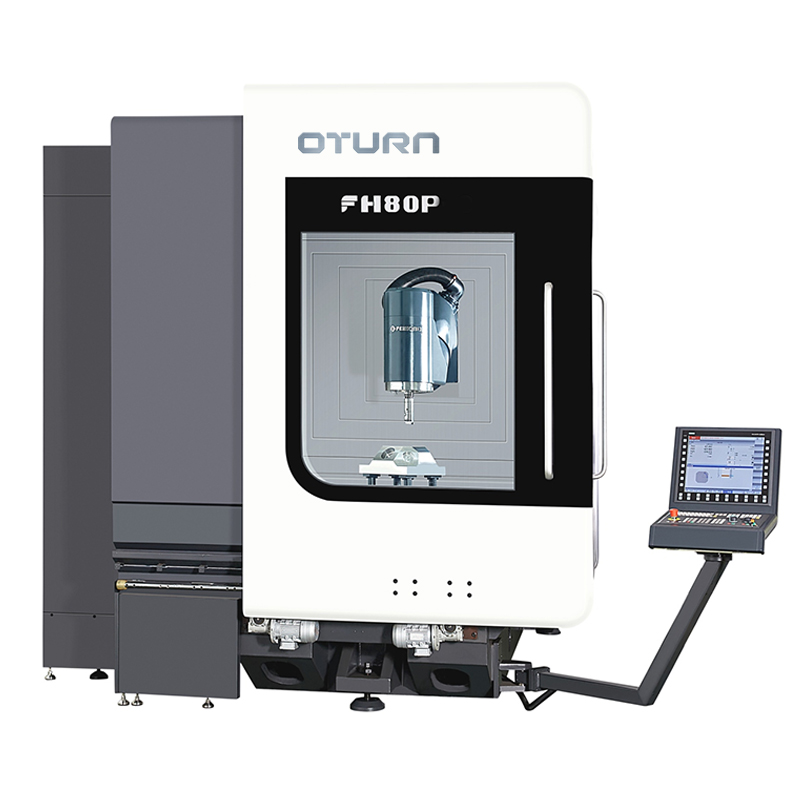

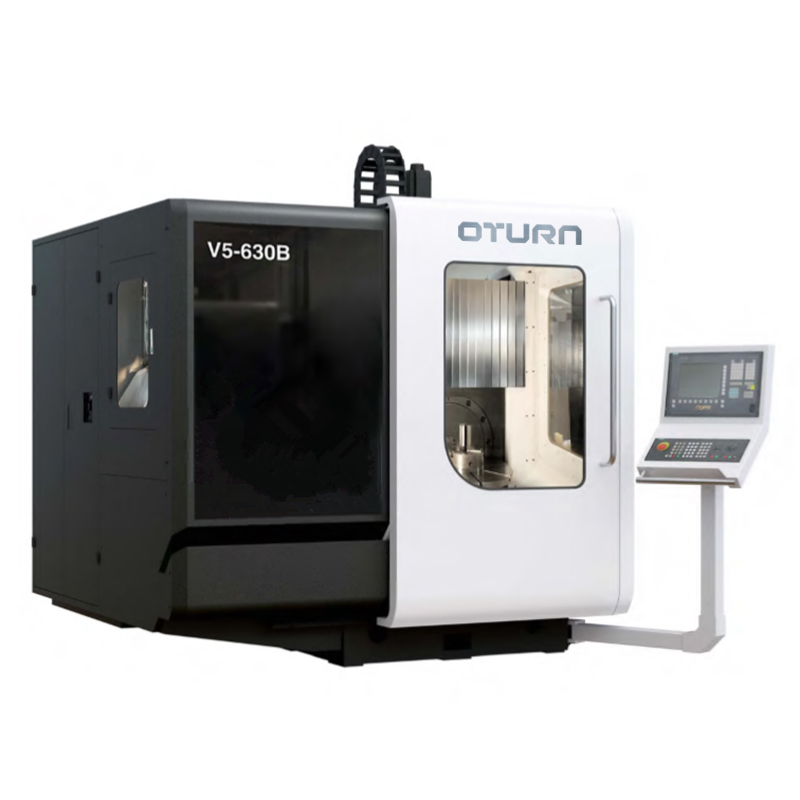

Top China CNC Machining Center Manufacturer for Precision Engineering

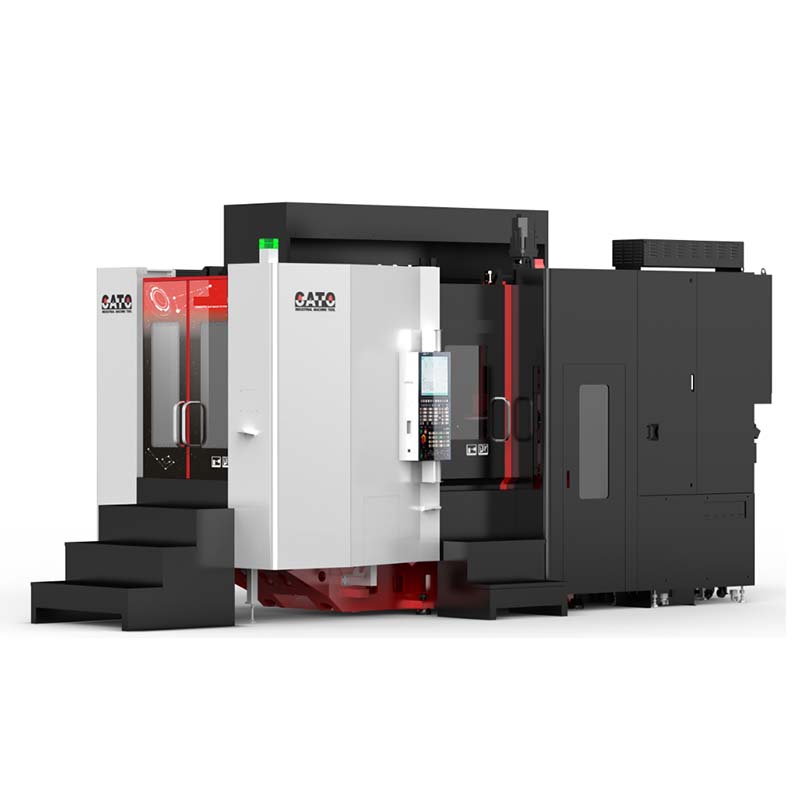

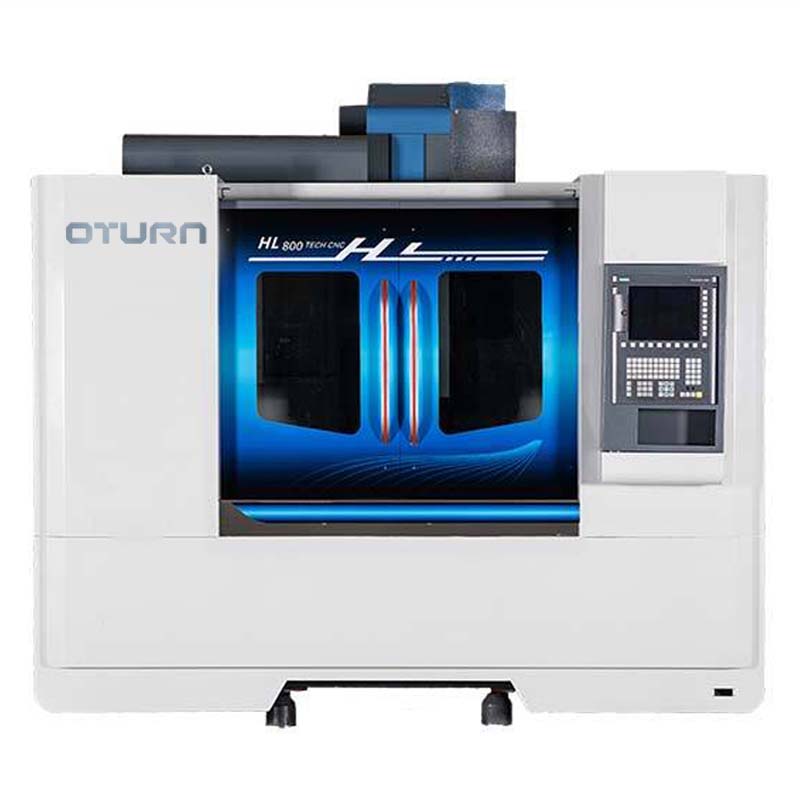

As a B2B purchaser, I'm always on the lookout for high-quality, reliable manufacturing solutions. That’s why I’m thrilled to share about the China CNC Machining Center. This advanced technology not only offers precision machining but also delivers a wide range of customization options to meet diverse project needs. When I sought a reputable manufacturer, I found many in China that excel in this field. They combine cutting-edge technology with skilled craftsmanship, ensuring every part meets exact specifications. The efficiency and speed of these CNC machining centers significantly reduce production lead times, giving me a competitive edge. Working with a trusted manufacturer in China has streamlined my supply chain and improved my product quality. Whether I need prototypes or large-scale production, the versatility of these machining centers makes them an essential part of my operations. I'm confident that choosing a China CNC Machining Center will enhance my business offerings and strengthen client relationships.

China CNC Machining Center Application Sets the Industry Standard

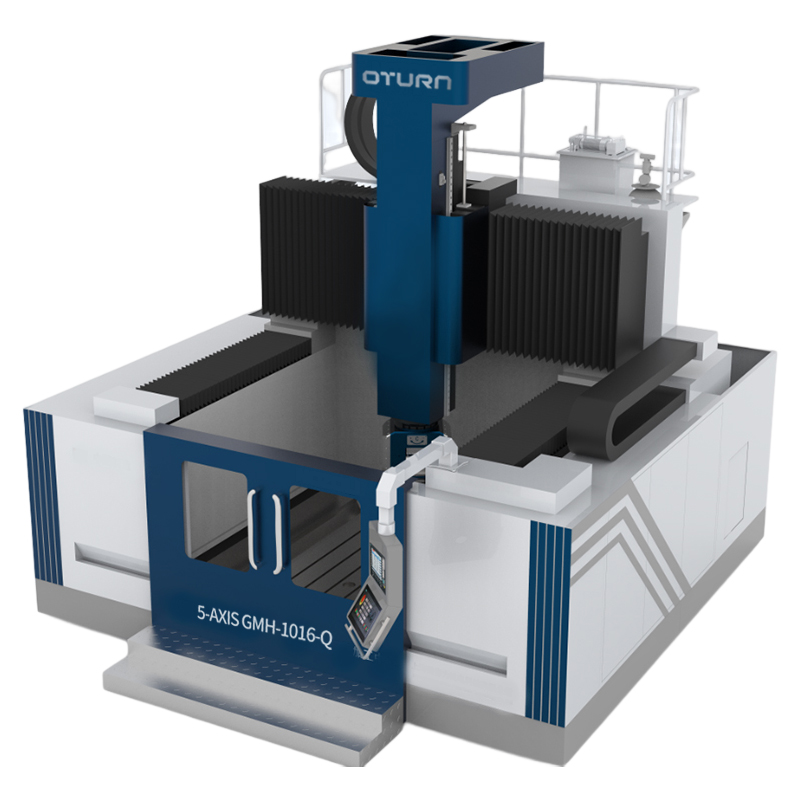

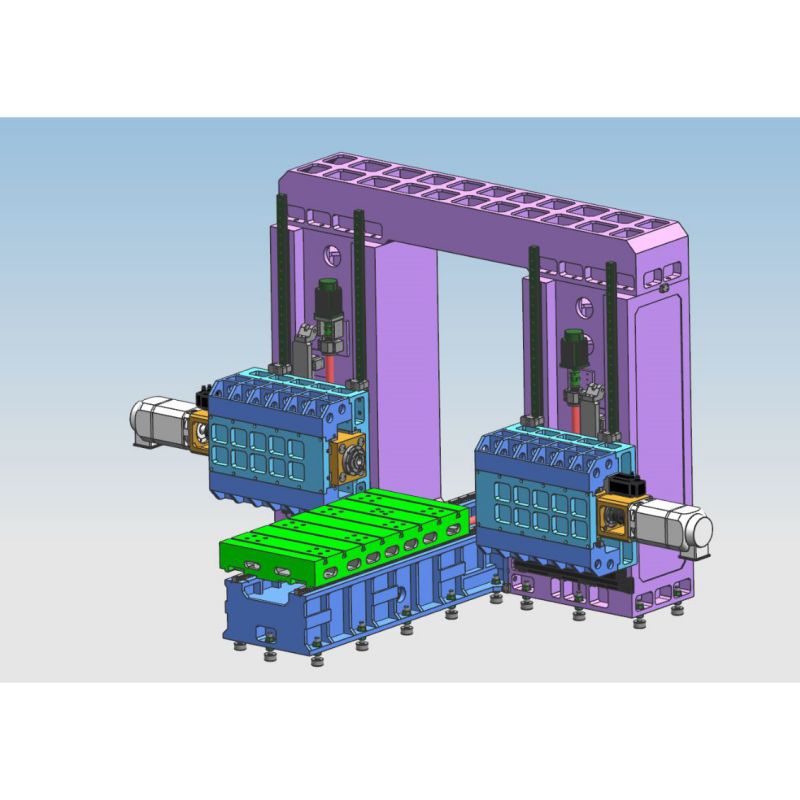

The CNC machining center industry in China has witnessed remarkable growth, setting increasingly high standards for precision and efficiency. With advanced technology and rigorous quality control, manufacturers are equipped to meet the diverse demands of global buyers. The application of CNC machining centers spans various sectors, including automotive, aerospace, electronics, and medical industries. This flexibility allows companies to produce intricate parts with exceptional accuracy, significantly reducing lead times and production costs. What truly sets the industry standard is the integration of innovative features such as automated tool changers, multi-axis machining capabilities, and real-time monitoring systems. These advancements enhance productivity, ensuring that manufacturers can deliver high-quality components that meet international specifications. Furthermore, the emphasis on sustainable practices is reshaping manufacturing processes, leading to reduced waste and energy consumption, which is increasingly important to environmentally conscious buyers. As global sourcing becomes more competitive, the ability to provide customized solutions while maintaining strict quality standards is paramount. By leveraging advanced CNC technology, companies can not only fulfill current market demands but also anticipate future trends, ensuring they remain ahead in the dynamic landscape of manufacturing. This commitment to excellence and innovation positions the Chinese CNC machining sector as a leader on the global stage.

China CNC Machining Center Application Sets the Industry Standard

| Application Area | CNC Machining Type | Material Used | Precision Level | Production Speed (units/hour) | Industry Standard Compliance |

|---|---|---|---|---|---|

| Aerospace | Milling | Titanium Alloy | ±0.005 mm | 10 | AS9100 |

| Automotive | Turning | Aluminum Alloy | ±0.01 mm | 20 | ISO/TS 16949 |

| Medical Devices | Milling | Stainless Steel | ±0.005 mm | 15 | ISO 13485 |

| Electronics | EDM (Electrical Discharge Machining) | Copper | ±0.002 mm | 30 | IPC-A-610 |

| Energy | Laser Cutting | Carbon Steel | ±0.1 mm | 25 | API Q1 |

Related Products