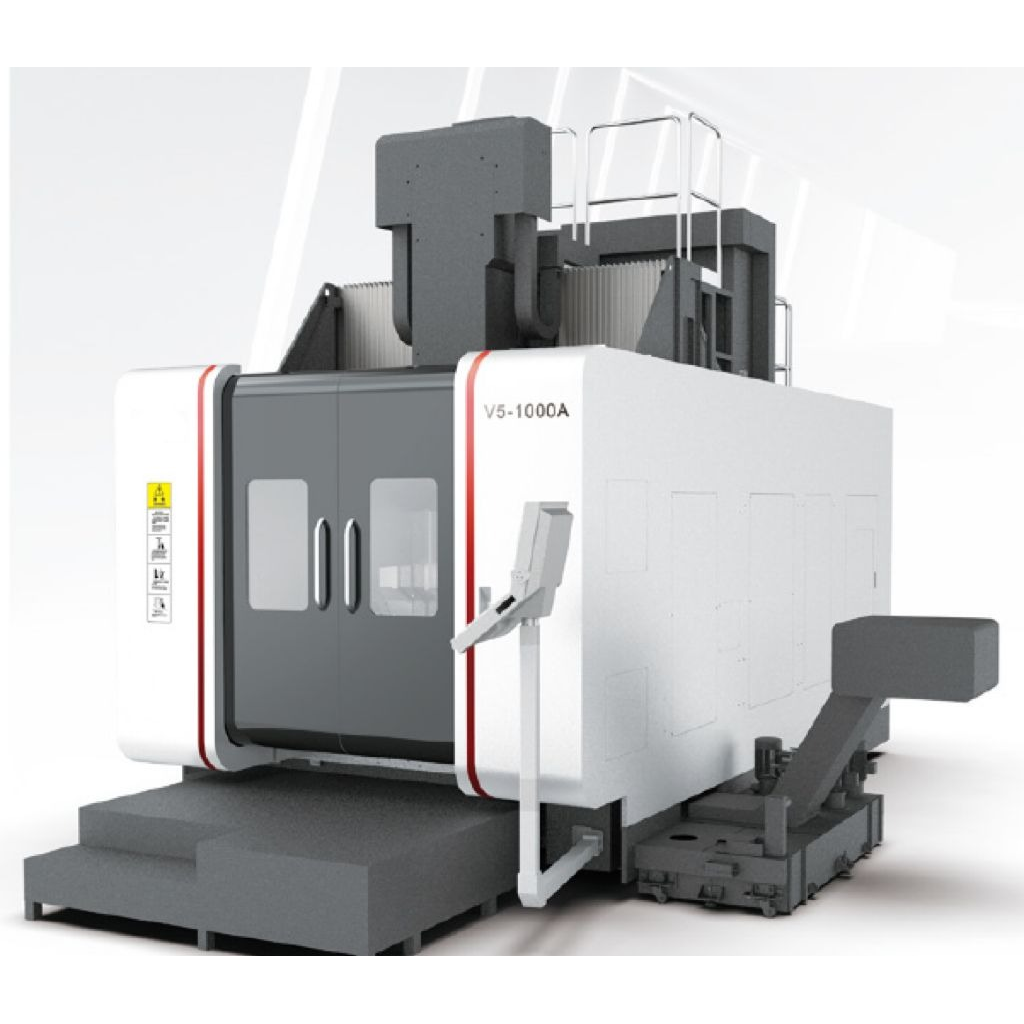

China 3 Axis Cnc Machining Manufacturers - V5-1000A 5-axis machining center – Oturn

China 3 Axis Cnc Machining Manufacturers - V5-1000A 5-axis machining center – Oturn Detail:

Five-Axis Vertical Machining Center

The V5-1000A five-axis machining center adopts a stable closed gantry structure and is equipped with a standard electric spindle, a two-axis direct-drive CNC turntable and a horizontal chain servo tool magazine. It can realize high-speed, high-precision, and efficient machining of complex parts. It is widely used in new Manufacturing of energy vehicles, aviation integral blisks, steam turbine impellers, molds and other products.

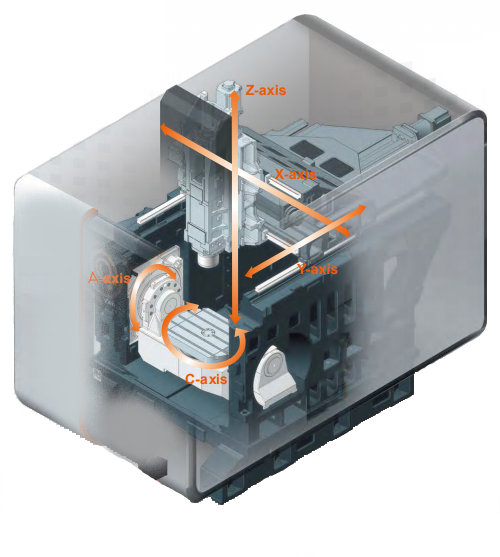

1. Overall layout of the machine

The V5-1000A five-axis machining center adopts a stable gantry structure, the column is fixed on the base, the beam moves longitudinally along the column (Y direction), the slide plate moves laterally along the beam (X direction), and the headstock moves vertically along the slide plate (Z direction) . The workbench adopts the self-developed direct-drive cradle structure, and various performance indicators have reached the international advanced level.

2. Feeding system

The X, Y, Z axes adopt ultra-high rigidity, high-precision roller linear guides and high-performance ball screws, with low dynamic and static friction, high sensitivity, low vibration at high speed, no creep at low speed, high positioning accuracy, and excellent servo drive performance.

X, Y, Z axis servo motors are connected with high precision ball screws through precision reducers, with flexible feeding, accurate positioning and high transmission precision.

The Z-axis servo motor has a brake function. In the case of power failure, it can automatically hold the brake to hold the motor shaft tightly so that it cannot rotate, which plays a role in safety protection.

3. Electric spindle

The motorized spindle adopts the self-developed BT50 motorized spindle (HSKA100 motorized spindle is optional), and the end is equipped with a ring spray joint to cool the tool. It has the advantages of high speed, high precision, high dynamic response, etc., and can realize stepless speed regulation , built-in high-precision encoder, can achieve directional accurate stop and rigid tapping.

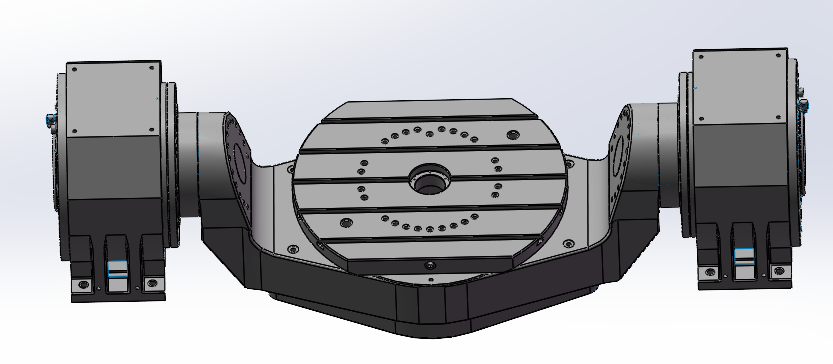

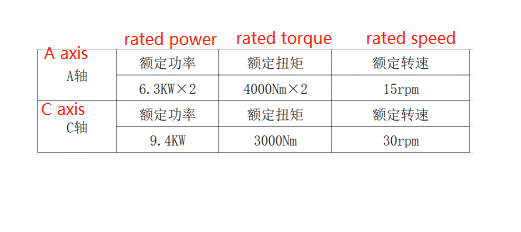

4. Turntable

The self-developed dual-axis direct-drive cradle turntable is equipped with a high-precision absolute encoder and is cooled by a water cooler at a constant temperature. It has the advantages of high rigidity, high precision, and high dynamic response. The worktable adopts 5-18mm radial T-slots, and the allowable load is 2000kg (evenly distributed)

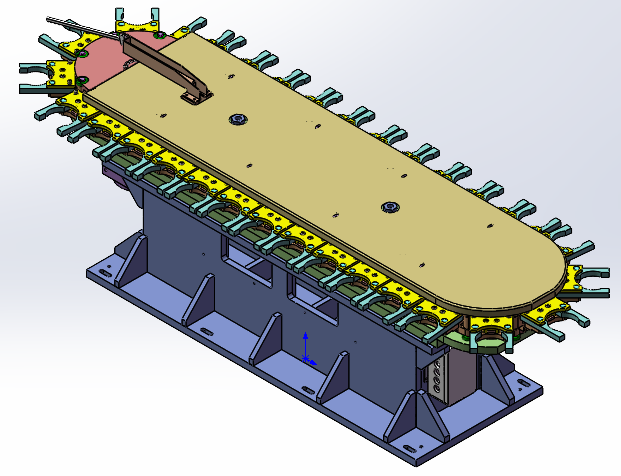

5. Tool magazine

The tool magazine adopts BT50 horizontal chain servo tool magazine, which can accommodate 30 tools.

6. Fully closed loop feedback system

X, Y, Z linear axes are equipped with HEIDENHAIN LC195S absolute value grating ruler; A and C rotary tables are equipped with HEIDENHAIN RCN2310 absolute value angle encoders to realize full closed-loop feedback of 5 feed axes, ensuring the machine has high precision and high precision Retention.

7. Cooling and pneumatic system

Equipped with large flow cooling pump and water tank to provide sufficient cooling for tools and workpieces. The headstock end face is equipped with cooling nozzles, which can be controlled by M code or control panel.

Equipped with a water cooler for constant temperature cooling, to ensure that the electric spindle and the direct drive turntable are in good working condition and can run efficiently for a long time.

The pneumatic system adopts pneumatic components for filtering, and realizes the functions of cleaning and blowing the taper hole of the spindle, protecting the air seal of the spindle bearing, and blowing and cleaning the grating ruler.

8. Centralized lubrication system

The slide block of the guide rail and the nut of the ball screw are all lubricated with thin grease, and the lubrication is provided regularly and quantitatively to ensure the precision and stability of the ball screw and the guide rail.

9. Oil and gas lubrication system

The electric spindle is equipped with imported oil and gas lubrication device, which can fully lubricate and cool the spindle. The sensor can provide abnormal lubrication alarm, which can effectively ensure the spindle can work stably at high speed for a long time.

10. Workpiece measuring system

The machine is equipped with Renishaw RMP60 radio probe, used in conjunction with the RMI receiver, the working frequency is 2400 MHz to 2483.5 MHz, the measurement one-way repeatability is less than or equal to 1um (480mm/min measurement speed, using a 50mm stylus), and the applicable working temperature is 5°C to 55°C.

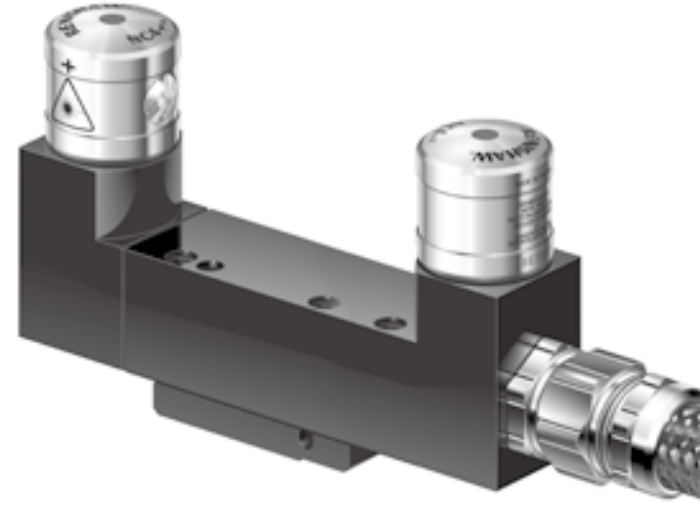

11. Tool measuring system

The machine is equipped with Renishaw NC4 laser tool setter, the measurement repeatability is ±0.1um, and the working temperature is 5°C to 50°C.

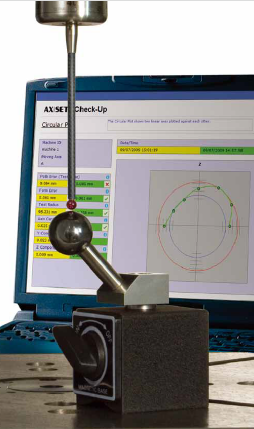

12. Five-axis precision calibration function

The machine is equipped with Renishaw’s AxiSet Check-Up Rotary Axis Line Checker kit, paired with the workpiece measurement system RMP60, enabling machine users to quickly and accurately check the condition of rotary axes and identify problems caused by temperature and humidity changes, machine collisions or wear and tear. problems, can quickly adjust and locate performance checks, benchmark and monitor how complex machines change over time.

13. machine protection

The machine adopts a fully enclosed overall protective cover that meets safety standards to prevent splashing of coolant and chips, ensure safe operation, and have a pleasant appearance. The X-direction of the machine is equipped with an armored protective cover, which can effectively protect the guide rail and ball screw.

14. machine working conditions

(1) Power supply: 380V±10% 50HZ±1HZ three-phase alternating current

(2) Ambient temperature: 5℃-40℃

(3) Best temperature: 20℃±2℃

(4) Relative humidity: 20-75%

(5) Air source pressure: 6±1 bar

(6) Air source flow: 500 L/min

15. Function introduction of CNC system

Siemens 840Dsl.730 CNC system configuration

| Item

|

Name

|

Remarks

|

| System functions | Minimum pulse equivalent | Linear axis 0.001 mm, rotary axis 0.001° |

| Feed rate per minute/revolution | ||

| Feed and rapid traverse | ||

| Feedrate override 0~120% | ||

| Spindle speed limit | ||

| Spindle constant speed cutting | ||

| Spindle monitoring | ||

| Spindle override 50~120% | ||

| Spindle speed display | ||

| FRAME | Realize coordinate system transformation and bevel machining | |

| Direct/indirect measurement system switching | ||

| Look-ahead function or look-ahead function | ||

| Lead screw pitch error compensation | ||

| Measurement System Error Compensation | ||

| Quadrant Error Compensation | ||

| Backlash compensation | ||

| Tool management | ||

| Hardware Configuration | Number of control axes | X, Y, Z, A, C five coordinate axes and one main axis |

| Simultaneous control of the number of axes | X, Y, Z, A, C five-axis linkage | |

| axis name | X, Y, Z, A, C, SP | |

| monitor | 15″ color LCD display, display text in Chinese/English | |

| Operation panel | OP015 full function CNC keyboard | |

| man-machine communication interface | Standard configuration TCU | |

| Machine control panel | SINUMERIK MCP 483C PN control panel, 50 mechanical keys with LED, with PROFINET, Industrial Ethernet interface | |

| Handheld operating unit | ||

| Standard keyboard interface | ||

| Ethernet interface | Integrated on NCU (open workshop networking function) | |

| USB port | 3 x 0.5 A USB integrated on TCU | |

| PLC program | PLC317-3PN/DP | |

| Interpolation function | Feed pause | |

| thread cutting | ||

| Simultaneous cutting | ||

| Three-coordinate linear interpolation | ||

| Arbitrary two-coordinate circular interpolation | ||

| Helical interpolation | ||

| Tapping / Rigid Tapping | ||

| programming | Excessive chamfering/rounding | |

| program editor | Comply with DIN66025 standard, with high-level language programming features | |

| Absolute or incremental programming | ||

| User variable, settable | ||

| Program jumps and branches | ||

| macro program | ||

| Coordinate system translation and rotation | ||

| Simultaneous programming and machining | ||

| Program instruction to return to the reference point | ||

| Contour programming and canned cycle programming | ||

| Mirroring and scaling | ||

| plane selection | ||

| Workpiece coordinate system | ||

| Drilling and milling canned cycle | ||

| Zero offset | ||

| block search | ||

| Program number search | ||

| Background editing | ||

| program protection | ||

| Select program by directory | ||

| Arithmetic and trigonometric functions | ||

| Comparison and logical operations | ||

| Five-axis machining software package | Five-axis transformation; five-axis tool compensation; rotation function around the tool center (RTCP) | |

| Safety protection function | Programmable machining area limits | |

| Program test function | ||

| emergency stop | ||

| Software limit monitoring | ||

| Contour monitoring | ||

| Contour collision detection | ||

| Static monitoring | ||

| Location monitoring | ||

| speed monitoring | ||

| Processing area restrictions | ||

| torque limit | ||

| Safety functions Clock monitoring measurement circuits, overheating, battery, voltage, memory, limit switches, fan monitoring | ||

| Operation method | AUTOMATIC | |

| JOG (manual) adjustment | ||

| Handwheel operation | ||

| MDA manual data entry | ||

| NC and PLC diagnostics with text display, screen saver | ||

| operation and display | Self-diagnostic function display | Including REF mode, incremental mode (x1, x10, x100) |

| Current location display | ||

| Graphical display | ||

| program display | ||

| program error display | ||

| Operation error display | ||

| Actual cutting speed display | ||

| Chinese and English menu display | ||

| Alarm information display | ||

| Multiple sets of M-code instruction sets | ||

| Support PROFINET bus data transfer | ||

| data communication | USB port | NC data, PLC data and programs are backed up to U disk for input and output data |

| Ethernet data transfer | Via the Ethernet interface |

Main parameter

| Item | Specifications | Unit | |||

| workbench

|

working desk size | φ1000×800 | mm | ||

| allowable maximum load | 2000 | kg | |||

| T-slot size | 5×18 | 个×mm | |||

| processing

scope

|

X axis | 1150 | mm | ||

| Y axis | 1300 | mm | |||

| Z axis | 900 | mm | |||

| A-axis | -150~+130 | ° | |||

| C axis | 360 | ° | |||

| Distance from spindle end face to work table | Max | 1080 | mm | ||

| Min | 180 | mm | |||

|

Spindle

|

Cone hole | BT50 | |||

| Rated speed | 1500 | r/min | |||

| maximum speed | 10000 | ||||

| Output torque S1/S6 | 191/236 | N.m | |||

| Spindle motor power S1/S6 | 30/37 | kW | |||

|

Axis

|

move quickly | X axis | 25 | m/min | |

| Y axis | 25 | ||||

| Z axis | 25 | ||||

| Turntable maximum speed | A-axis | 15 | rpm | ||

| C axis | 30 | rpm | |||

| X/Y/Z axis motor power | 3.1/4.4/2 | kW | |||

| A/C axis Motor power | 6.3 *2/ 9.4 | kW | |||

| A-axis | Rated torque | 4000×2 | N.m | ||

| C axis | Rated torque | 3000 | N.m | ||

| maximum feed rate | X/Y/Z | 25 | m/min | ||

| A/C | 15/30 | rpm | |||

|

Tool magazine

|

Tool magazine form | horizontal | |||

| tool selection method | Two-way nearest tool selection | ||||

| Tool magazine capacity | 30 | T | |||

| Maximum tool length | 400 | mm | |||

| Maximum tool weight | 20 | kg | |||

| Maximum cutter head diameter | full of knives | φ125 | mm | ||

| Adjacent empty tool | φ180 | mm | |||

|

position precision |

Executive standard | GB/T20957.4(ISO10791-4) | |||

| X-axis/Y-axis/Z-axis | 0.008/0.008/0.008 | mm | |||

| B axis / C axis | 8″/8″ | ||||

| repeat

position precision |

X-axis/Y-axis/Z-axis | 0.006/0.006/0.006 | mm | ||

| B axis / C axis | 6″/6″ | ||||

| Machine weight | 33000 | kg | |||

| total electrical capacity | 80 | KVA | |||

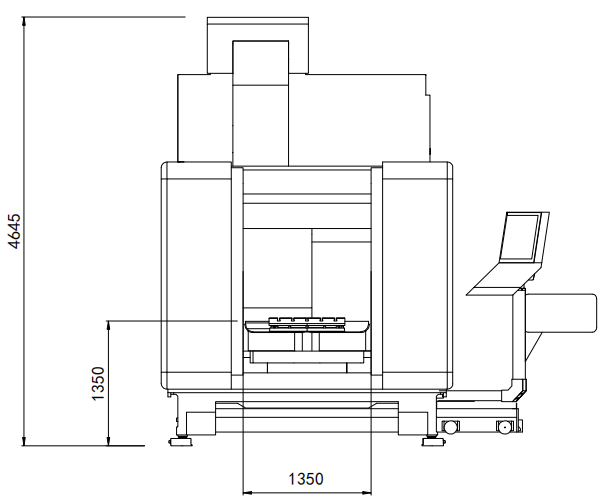

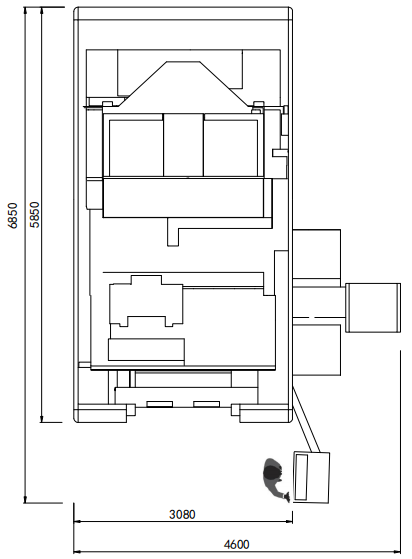

| machine outline size | 7420×4770×4800 | mm | |||

Configuration List

Standard

|

|

1. Main components (including base, column, beam, slide plate, spindle box) |

| 2. X, Y, Z three-axis feed system | |

| 3. Cradle type turntable AC1000 | |

| 4. Electric spindle | |

| 5. Electrical control system (including electrical cabinet, power module, servo module, PLC, operation panel, display, hand-held unit, electric cabinet air conditioner, etc.) | |

| 6. Hydraulic system | |

| 7. Pneumatic system | |

| 8. Centralized lubrication system | |

| 9. Water cooler | |

| 10. Chip conveyor, water tank, chip collector | |

| 11. Grating ruler | |

| 12. Rail protection cover | |

| 13. machine overall protective cover | |

| 14. Workpiece measuring system | |

| 15. Tool setting instrument | |

| 16. Five-axis precision calibration function | |

|

|

1. 1 certificate of conformity

2. Packing list 1 copy 3. 1 set of machine manual (electronic version) 4. machine backup data 1 set (U disk) 5.840D alarm diagnosis manual 1 set (electronic version)/828D diagnosis guide 1 copy (electronic version) 6.840D milling operation manual 1 copy (electronic version)/828D operation manual 1 copy (electronic version) 840D programming manual 1 basic part (electronic version) / 828D programming manual 1 (electronic version) |

|

Item |

Brands |

|

X/Y/Z axis motor and drive |

Siemens, Germany |

|

energy chain |

germany igus |

|

screw bearing |

Japan NSK/NACHI |

|

Linear Guides |

Schneeberg, Germany |

|

Tool magazine |

Okada |

|

reducer |

STOBER, Germany |

|

Centralized lubrication |

Japan |

|

Ball screw |

SHUTON, Spain |

|

Pneumatic Components |

Japan SMC |

|

Electric cabinet air conditioner |

China |

|

water cooler |

China |

|

grating ruler |

HEIDENHAIN, Germany |

|

Workpiece measuring system |

Renishaw, UK |

|

Tool measuring system |

Renishaw, UK |

|

Patrs with machine |

Specifications |

Quantity |

|

Machine mattress iron |

|

8 sets |

|

Anchor bolts |

|

8 sets |

|

rings |

M30 |

2 pieces |

|

rings |

M36 |

2 pieces |

|

suspenders |

|

1 set |

|

Allen key |

10 |

1 |

|

Allen key |

12 |

1 |

|

Allen key |

14 |

1 |

|

Allen key |

19 |

1 |

|

Z-axis mount |

|

1 |

|

X-axis mount |

|

1 |

|

Y-axis fixing |

|

1 |

Thanks For Your Attention!

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!