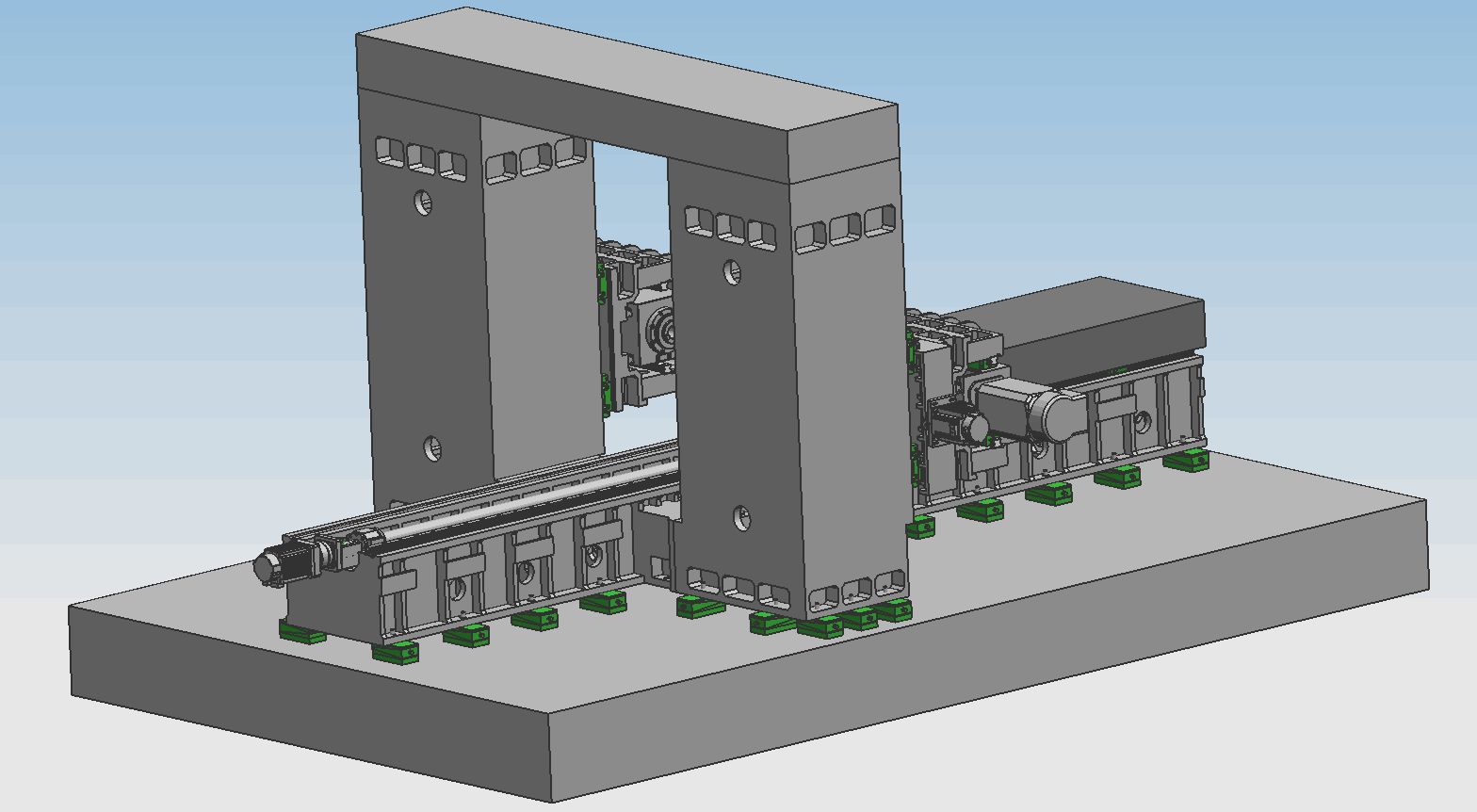

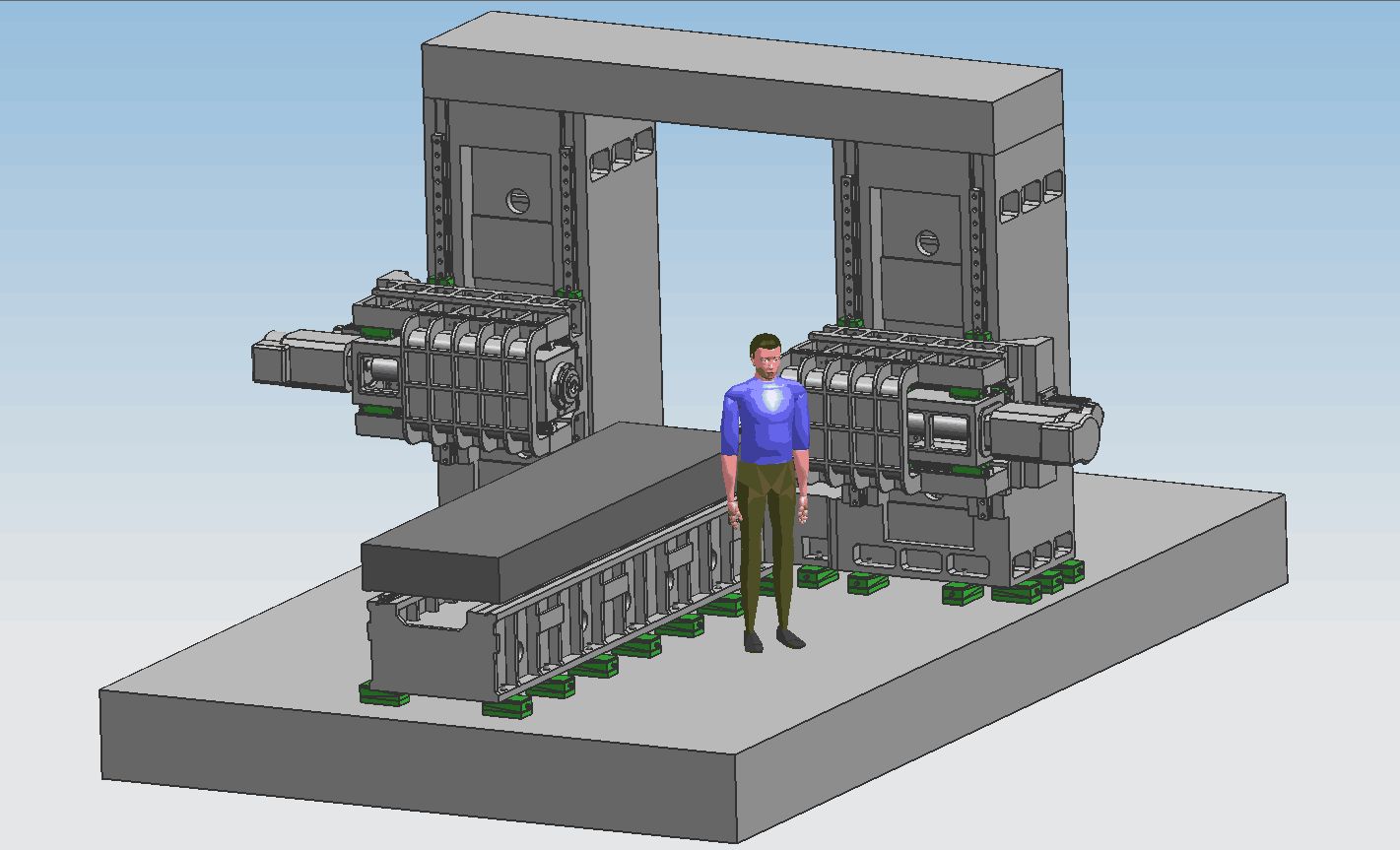

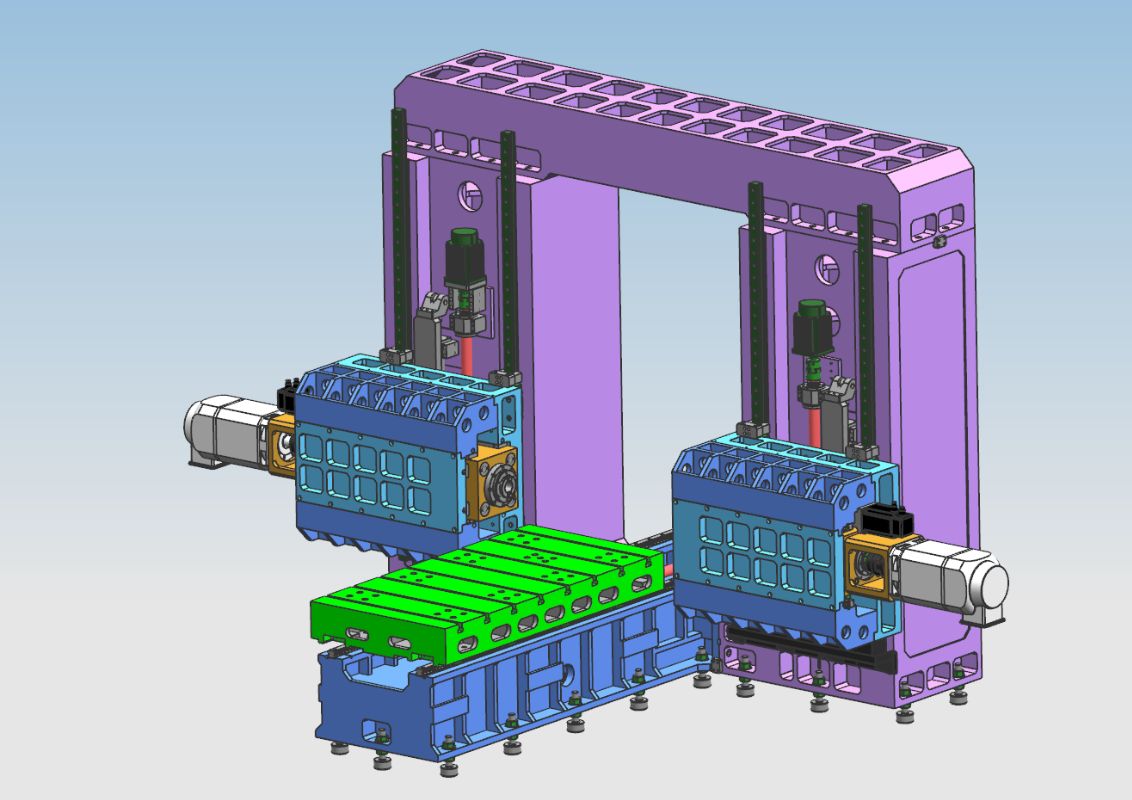

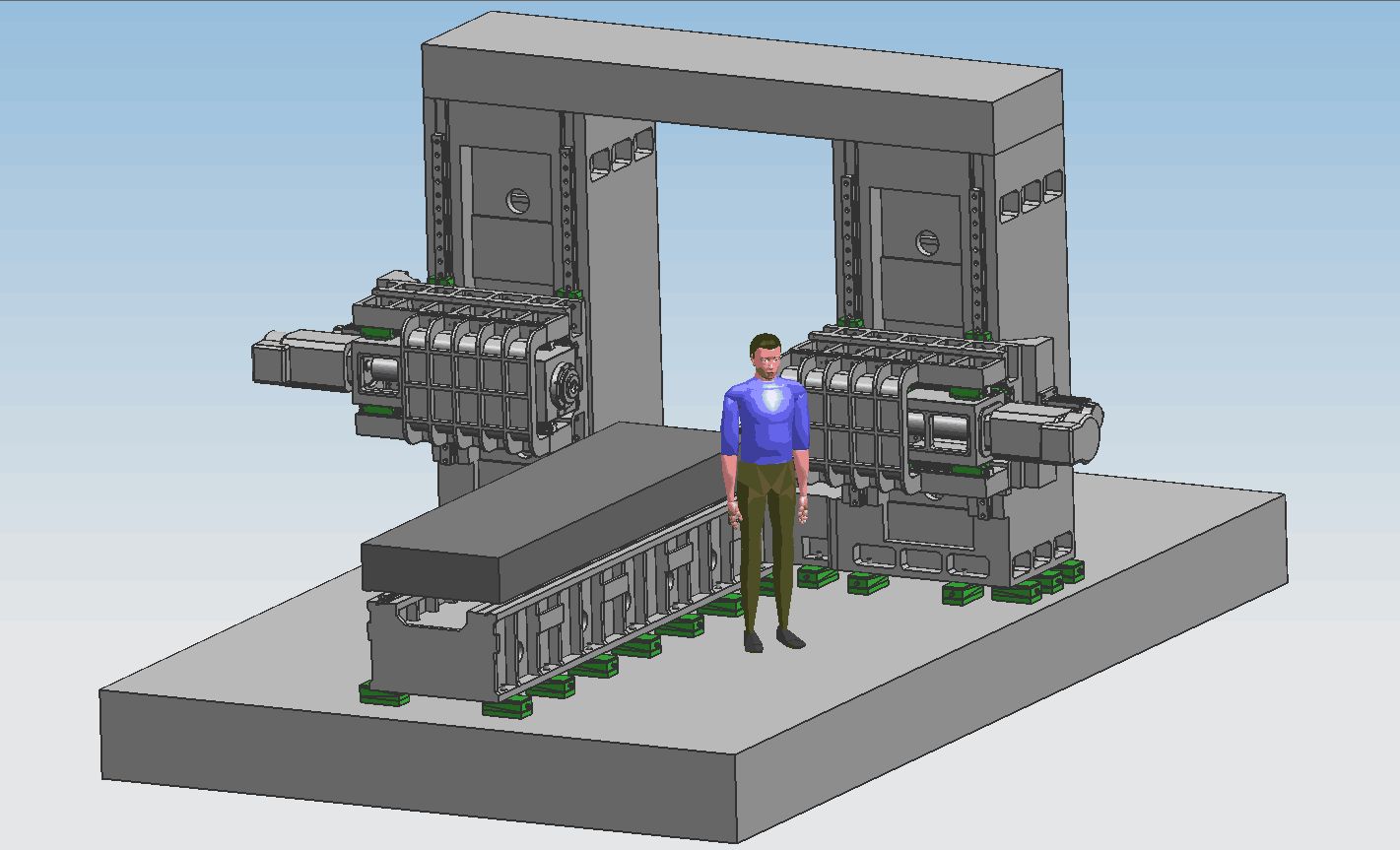

BOSM -6010 Opposed-Head Boring Milling Machine

1. Use of machine :

BOSM- 6000*1000 fixed-beam CNC gantry double-column head-to-head boring and milling machine is a special machine tool for processing excavator arms/sticks. Pillow, can realize the rapid processing of the workpiece, the workpiece can be drilled, milled, and bored within the effective stroke range, the workpiece can be processed in place at one time (no need for secondary clamping), the loading and unloading speed is fast, the positioning speed is fast, and the processing accuracy is high. High, high processing efficiency.

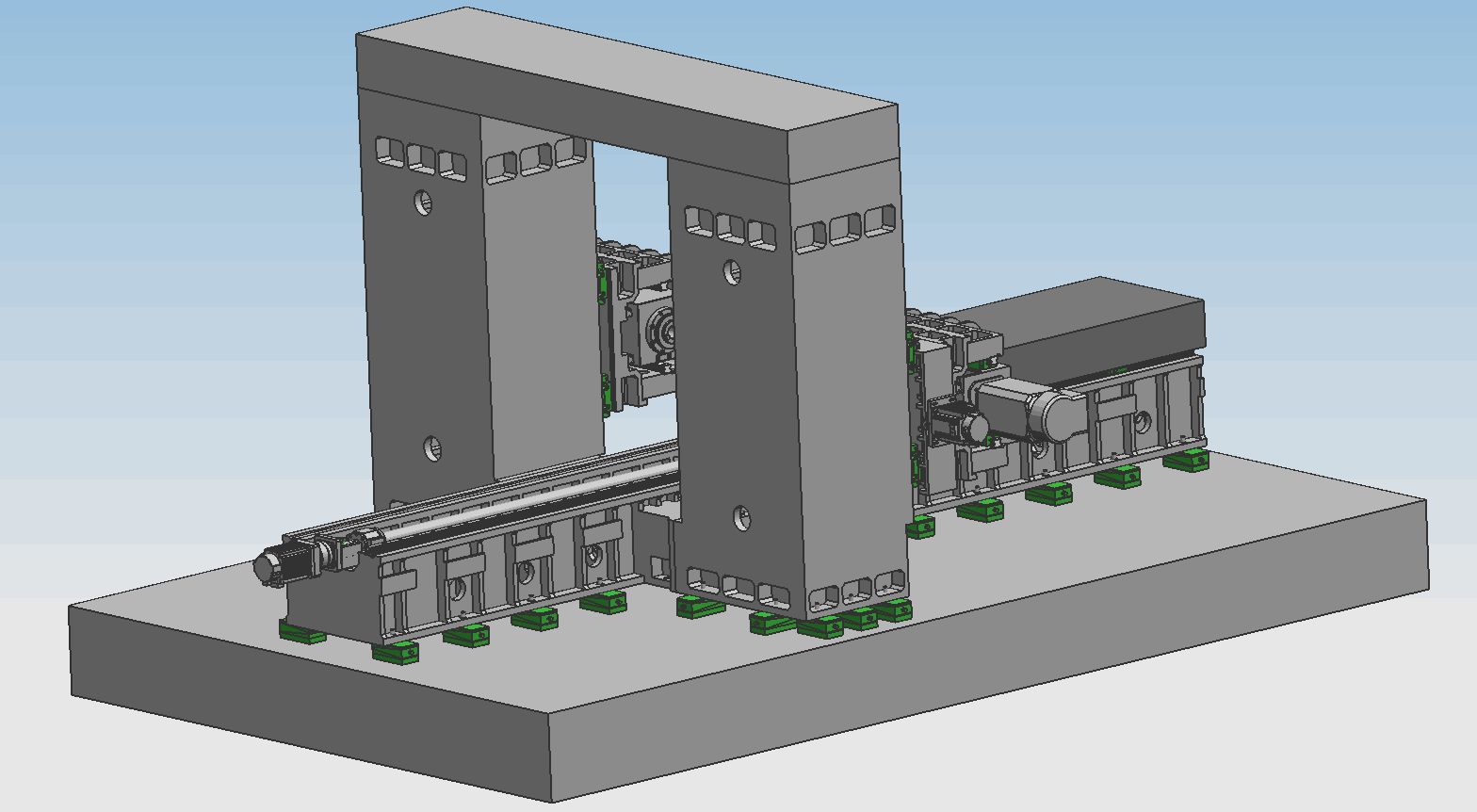

2.Machinel structure features:

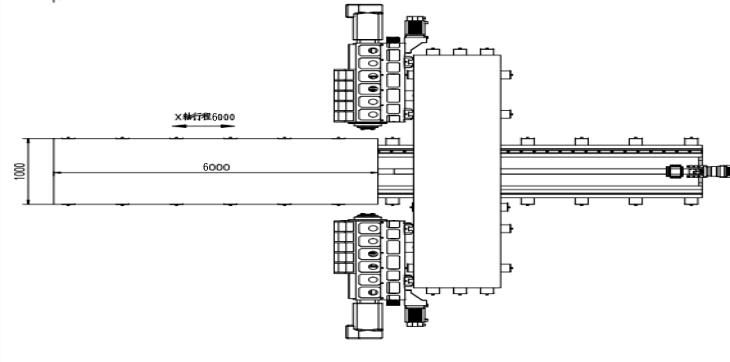

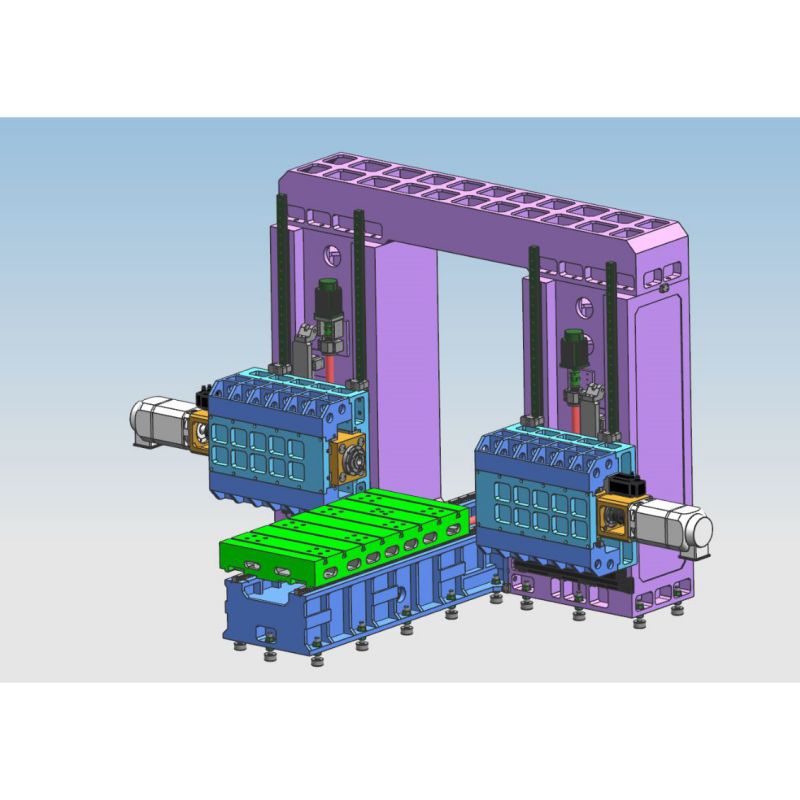

The main components of the machine tool: bed, workbench, left and right columns, beams, gantry connecting beams, saddles, rams, etc., large parts are made of resin sand molding, high-quality gray iron 250 casting, annealed in hot sand pit → vibration aging → heat treatment Furnace annealing→vibration aging→rough machining→vibration aging→hot furnace annealing→vibration aging→finishing, completely eliminate the negative stress of the parts, and keep the performance of the parts stable. The fixed bed, the left and right columns, the gantry, and the workbench move ; It has the functions of milling, boring, drilling, countersinking, tapping, etc. The tool cooling method is external cooling . The machine tool contains 5 feed axes, which can realize 4-axis linkage and 5-axis single-action. There are 2 power heads. The axis of the machine tool and the power head are shown in the figure below.

2.1The main structure of the axial transmission feed part

2.1.1. X-axis: The worktable reciprocates laterally along the guide rail of the fixed bed.

X 1- axis drive: AC servo motor plus high-precision planetary reducer is driven by ball screw to drive the movement of the workbench to realize linear motion of the X-axis

Guide rail form: lay two high-strength precision linear guide rails.

2.1.2 Z1 axis: The power head and a saddle are vertically installed on the front side of the column, and reciprocate up and down along the column guide rail.

Z1-axis transmission: AC servo motor and synchronous wheel are used to drive the ball screw to drive the saddle to realize Z- axis linear motion

2.1.3 Z2 axis: The power head and a saddle are vertically installed on the front side of the column, and reciprocate up and down along the column guide rail.

Z2-axis transmission: AC servo motor and synchronous wheel are used to drive the ball screw to drive the saddle to realize Z- axis linear motion.

2.1.4 Y1 axis: The power head saddle is installed vertically on the front side of the right column, and reciprocates left and right along the column guide rail.

Y1-axis transmission: AC servo motor plus high-precision planetary reducer is used to drive the ram to move through the ball screw to realize the linear motion of the Y1- axis

2.1.5 Y2 axis: The power head saddle is vertically installed on the front side of the right column, and reciprocates left and right along the column guide rail.

Y2-axis transmission: AC servo motor plus high-precision planetary reducer is used to drive the ram to move through the ball screw to realize the Y2- axis linear motion.

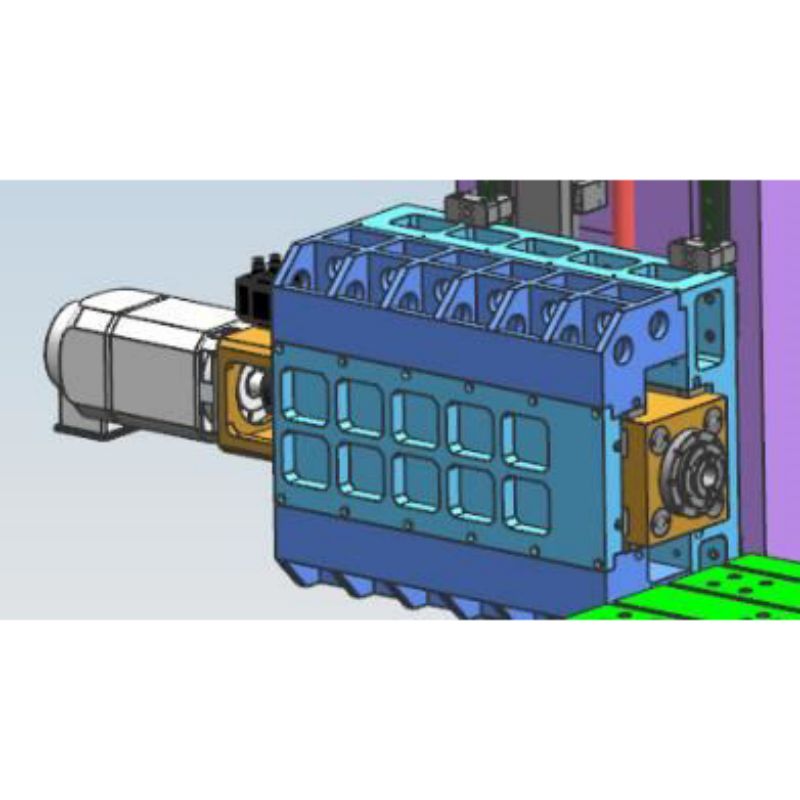

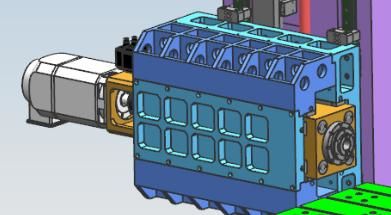

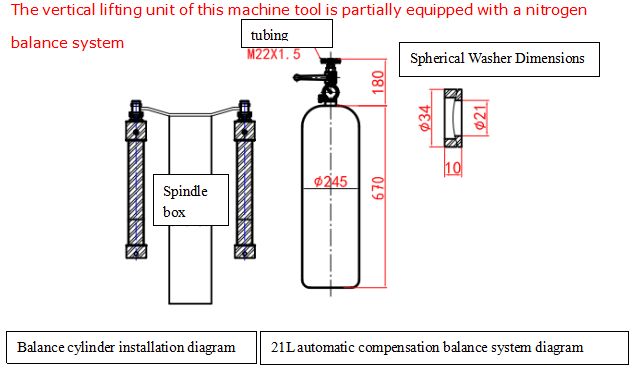

2.2 The moving direction of the drilling and milling power head (including the power head 1 and 2) is guided by 4 linear roller guide rail pairs, and the drive adopts AC servo motor to drive the synchronous belt (i=2) and precision ball screw pair transmission. The power head adopts servo The motor is decelerated by the synchronous belt and synchronous wheel, guided by the heavy-duty precision guide rail pair, and drives the vertical ball screw to rotate to realize the vertical movement of the power head . It is also equipped with a nitrogen balance bar to reduce the head-to-screw and servo motor. The Z-axis motor has an automatic brake function. In the event of a power failure, the automatic brake will hold the motor shaft tightly so that it cannot rotate. When working, when the drill bit does not touch the workpiece, it will feed rapidly; when the drill bit touches the workpiece, it will automatically switch to working feed. When the drill bit penetrates the workpiece, it will automatically switch to fast rewind; when the end of the drill bit leaves the workpiece and reaches the set position, the worktable will move to the next hole position to realize automatic circulation. The power head adopts the combination of wire and hard rail, which not only ensures the running speed of the equipment, but also greatly enhances the rigidity of the equipment . And it can realize the functions of blind hole drilling, milling, chamfering, chip breaking, automatic chip removal, etc., which improves labor productivity.

(left power head)

2.3. Chip removal and cooling

There are spiral and flat chain chip conveyors installed on both sides below the workbench, and the chips can be automatically discharged to the chip conveyor at the end through two stages of spiral and chain plates to realize civilized production. There is a cooling pump in the coolant tank of the chip conveyor, which can be used for external cooling of the tool to ensure the drilling performance and service life of the drill bit, and the coolant can be recycled.

3. Full digital numerical control system:

3.1. With chip breaking function, chip breaking time and chip breaking cycle can be set on the man-machine interface.

3.2. With the tool lifting function, the tool lifting height can be set on the man-machine interface. When drilling reaches this height, the drill bit is quickly lifted to the top of the workpiece, and then the chips are thrown away, and then fast forwarded to the drilling surface and automatically converted to work.

3.3. Centralized operation control box and handheld unit adopt numerical control system and are equipped with USB interface and LCD liquid crystal display. In order to facilitate programming, storage, display and communication, the operation interface has functions such as man-machine dialogue, error compensation, and automatic alarm.

3.4. The equipment has the function of previewing and re-inspecting the hole position before processing, and the operation is very convenient.

3.5. Automatic lubrication

Machine tool precision linear guide rail pairs, precision ball screw pairs and other high-precision motion pairs are equipped with automatic lubrication systems. The automatic lubricating pump outputs pressure oil, and the quantitative lubricator oil chamber enters the oil. After the oil chamber is filled with oil, when the system pressure rises to 1.4-1.75Mpa, the pressure switch in the system is closed, the pump stops, and the unloading valve unloads at the same time. When the oil pressure in the road drops below 0.2Mpa, the quantitative lubricator starts to fill the lubricating point and completes one oil filling. Due to the accurate oil supply of the quantitative oil injector and the detection of the system pressure, the oil supply is reliable, ensuring that there is an oil film on the surface of each kinematic pair, reducing friction and wear, and preventing the damage to the internal structure caused by overheating. , to ensure the accuracy and life of the machine tool. Compared with the sliding guide rail pair, the rolling linear guide rail pair used in this machine tool has a series of advantages:

①The motion sensitivity is high, the friction coefficient of the rolling guide rail is small, only 0.0025~0.01, and the driving power is greatly reduced, which is only equivalent to 1/10 of ordinary machinery.

② The difference between dynamic and static friction is very small, and the follow-up performance is excellent, that is, the time interval between the driving signal and the mechanical action is extremely short, which is conducive to improving the response speed and sensitivity of the numerical control system.

③It is suitable for high-speed linear motion, and its instantaneous speed is about 10 times higher than that of sliding guide rails.

④ It can realize gapless movement and improve the movement rigidity of the mechanical system.

⑤Produced by professional manufacturers, it has high precision, good versatility and easy maintenance.

4. Machine use environment:

Power supply: three-phase AC380V ± 10% , 50Hz ± 1 Ambient temperature: 0 ° ~ 45 °

5. Main technical parameters:

|

Model |

BOSM6010 |

|

|

Maximum processing workpiece size |

Length × width × height (mm) |

6000×1000×1500 |

|

Gantry maximum feed |

Width (mm) |

1300 |

|

working desk size |

Length X Width (mm) |

6000*1000 |

|

Horizontal ram type drilling head power head one two

|

Quantity (2) |

2 |

|

Spindle taper |

BT50 |

|

|

Drilling diameter (mm) |

Φ2-Φ60 |

|

|

Tapping diameter (mm) |

M3-M30 |

|

|

Spindle speed (r/min) |

30~6000 |

|

|

Servo spindle motor power (kw) |

37 |

|

|

Single spindle nose distance from table center (mm) |

150-650 |

|

|

Center distance of double spindle nose end (mm) |

300-1300 |

|

|

Left and right stroke of a single ram (mm) |

500 |

|

|

The distance between the center of the ram and the plane of the table (mm) |

200-1700 |

|

|

Up and down stroke of ram (mm) |

1500 |

|

|

Repeatability |

300mm*300mm |

±0.02 |

|

Machine Tool Dimensions |

Length × width × height (mm) |

according to drawings |

|

Gross weight (t) |

(approx.) 36 |

|

The above parameters are preliminary design parameters. In the actual design, there may be changes according to the processing requirements of the workpiece and the design requirements of the machine tool, so as to meet the requirements of your company's processing parts.