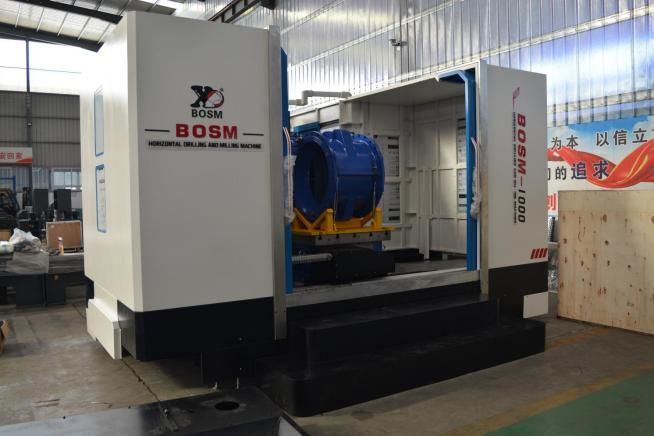

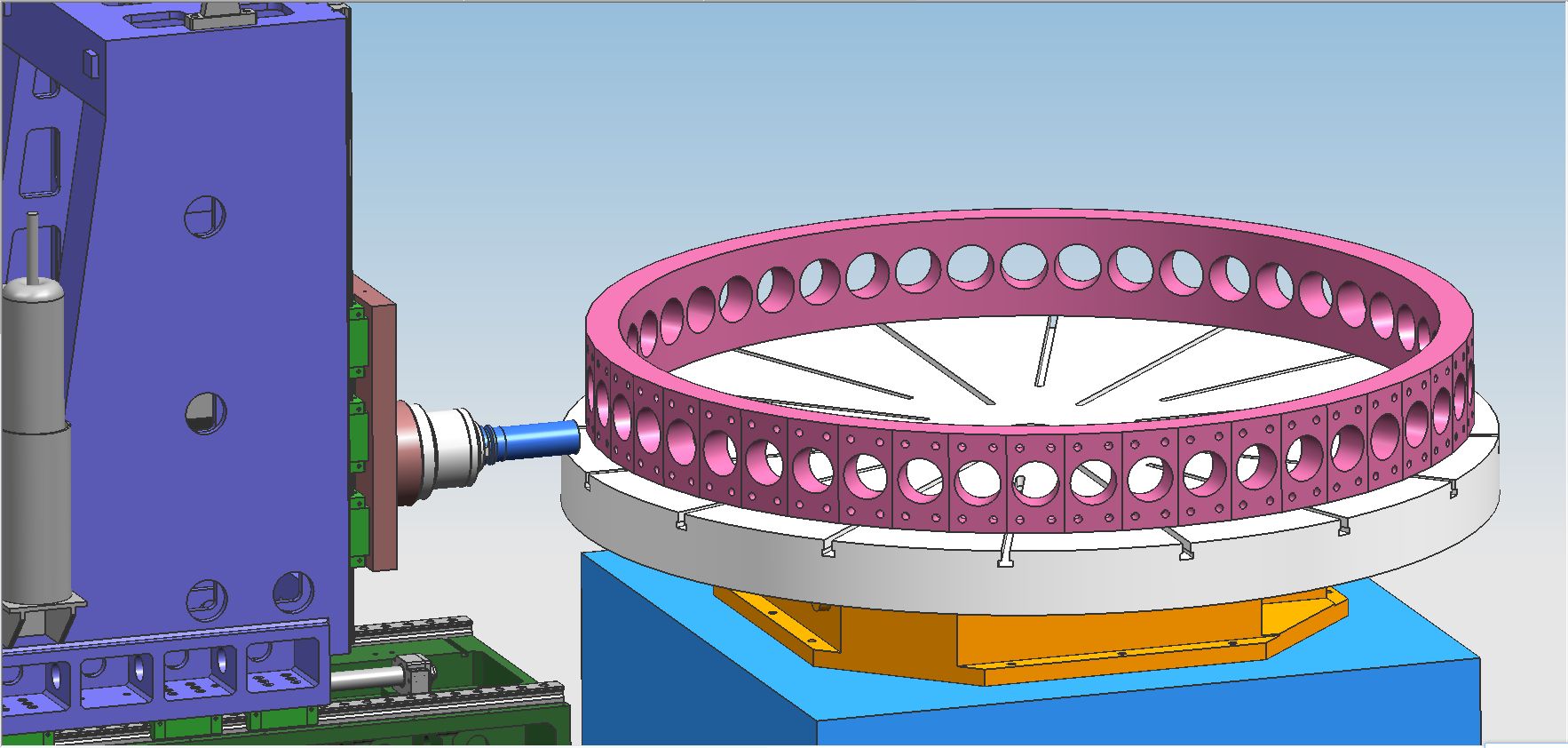

BOSM -4Z2000 High speed CNC drilling and milling machine

1.Equipment use:

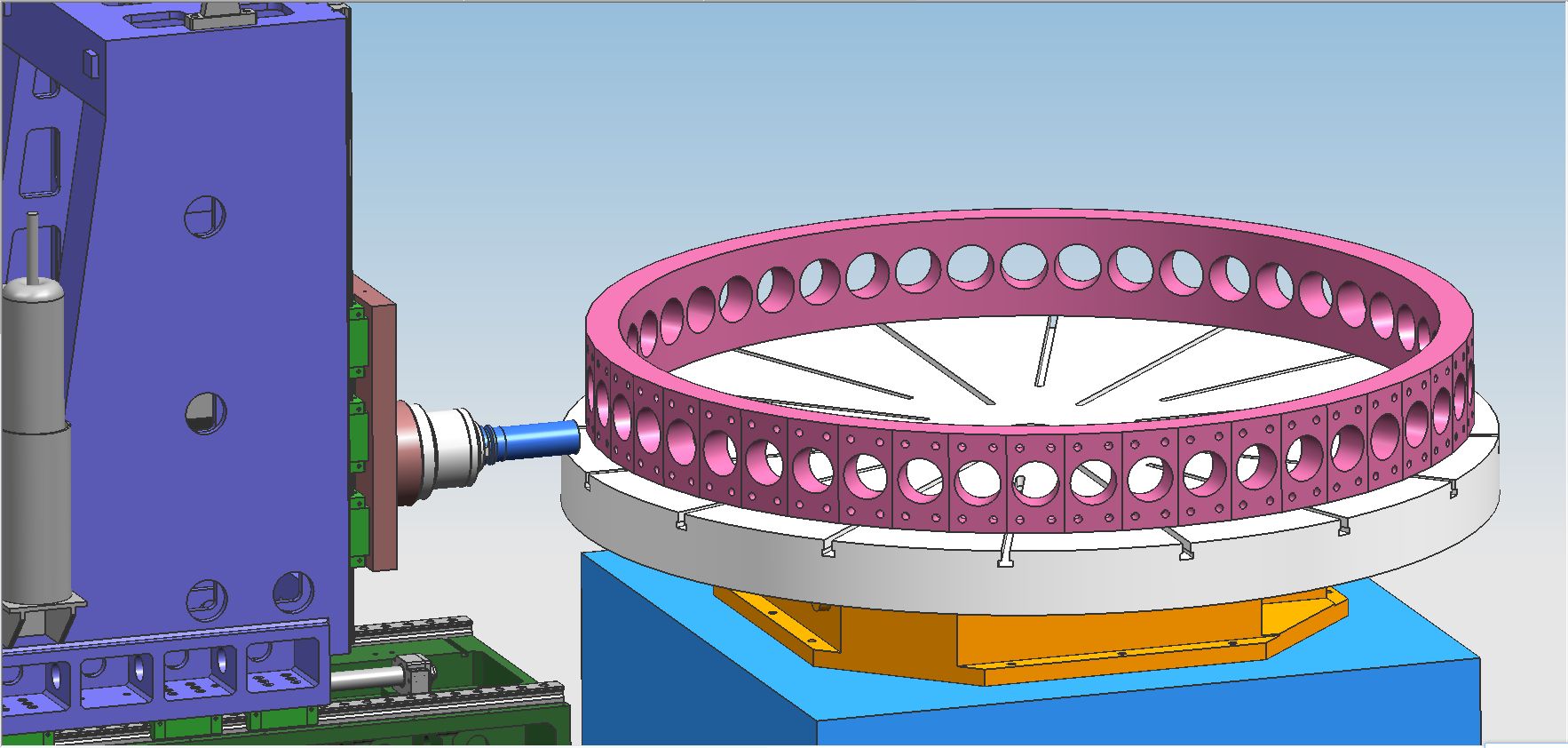

BOSM-1000 horizontal CNC drilling and milling machine is mainly used for multi-faceted efficient drilling, milling, tapping and boring processing of valves, valve blocks, reducers, flanges, discs, rings, slewing supports and other workpieces within the effective range of thickness. Drilling, milling, tapping and boring can be realized on single material parts and composite materials. The machining process of the Machine is digitally controlled, and the operation is very convenient. It can realize automation, high precision, multi-variety and mass production.

2. Equipment structure:

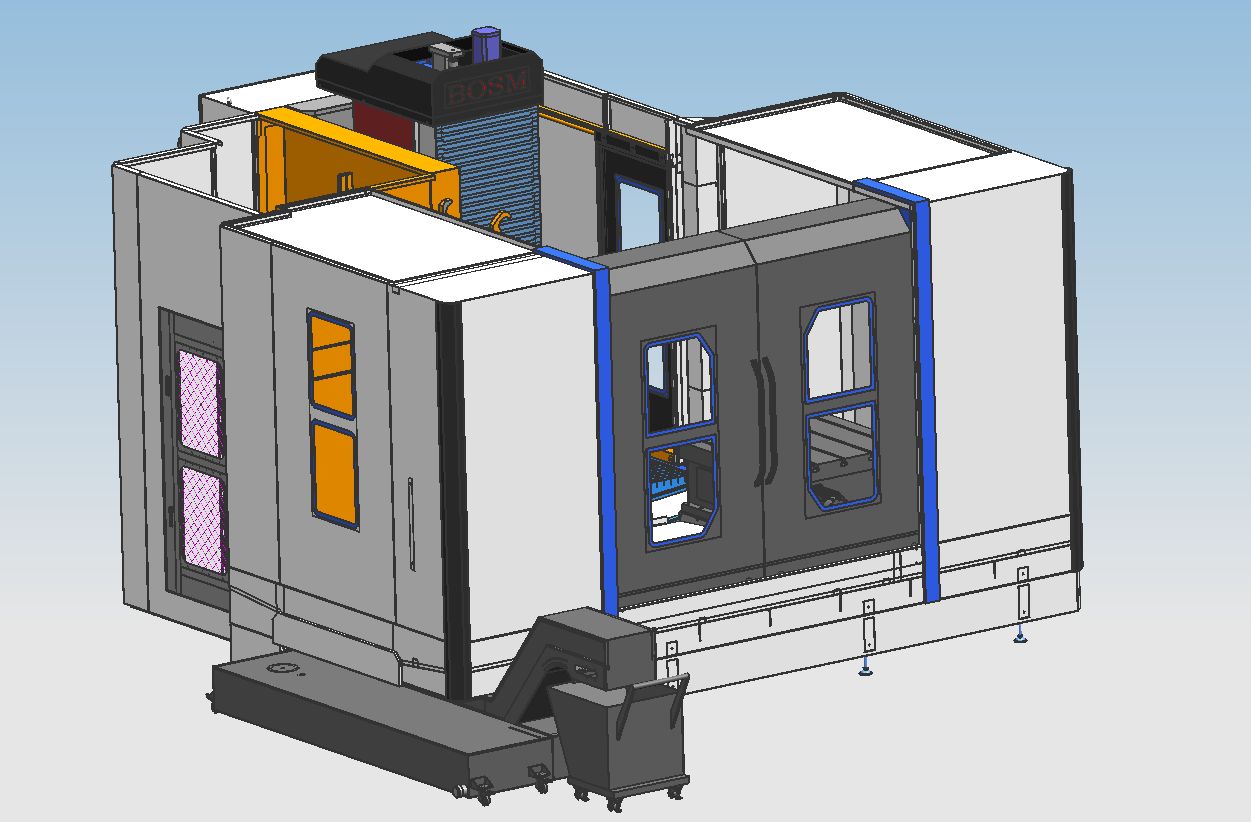

This equipment is mainly composed of bed, CNC indexing rotary table, movable column, movable saddle, drilling and milling power head, automatic lubrication device and protection device, circulating cooling device, digital control system, hydraulic system, electrical system and so on. The rolling linear guide rail is supported and guided, and the precision screw is driven. The Machine has high positioning accuracy and repeat positioning accuracy.

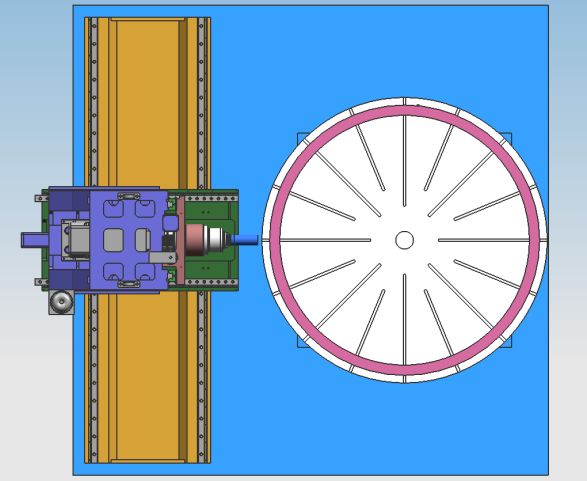

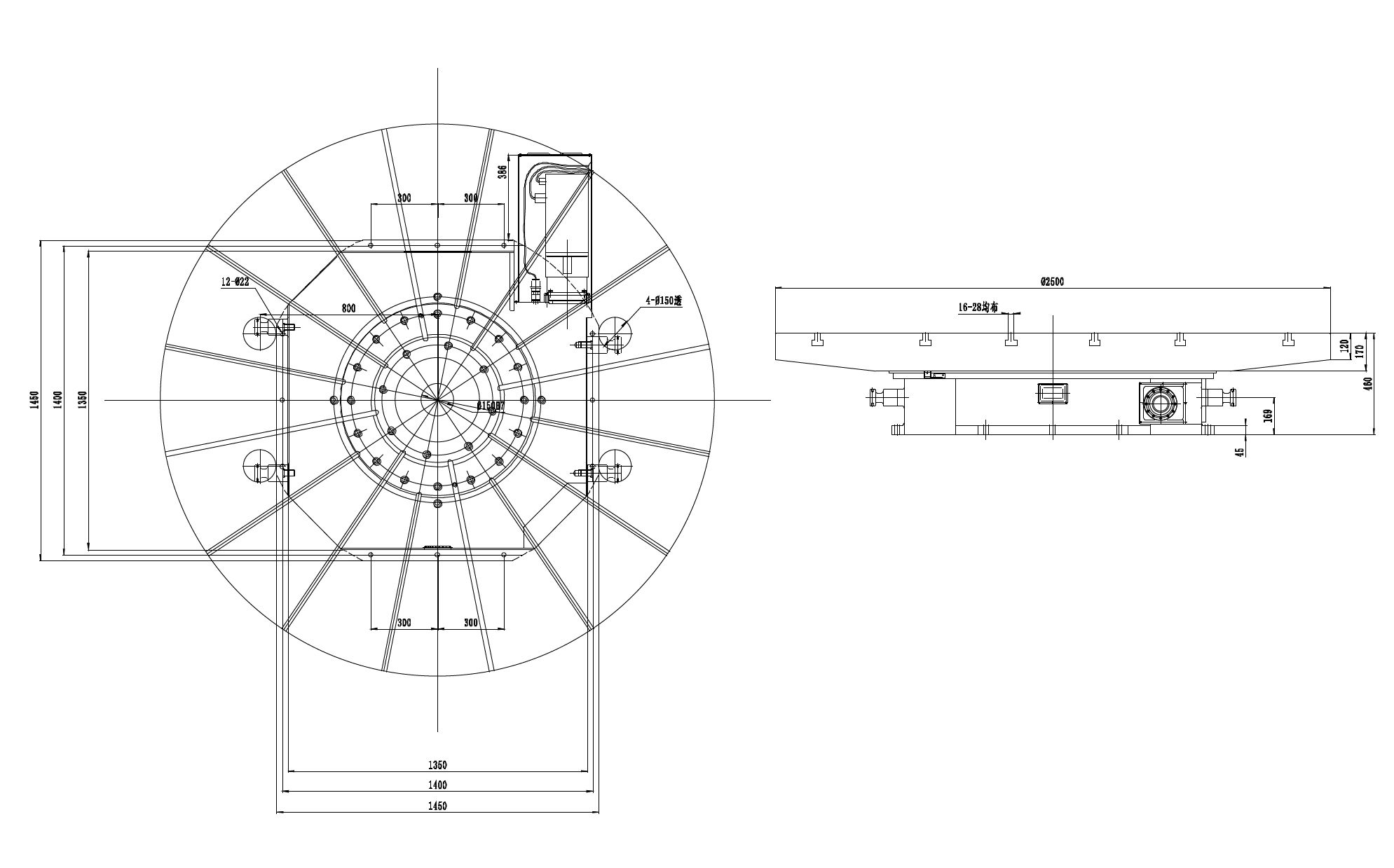

2.1. Bed worktable: The bed is made of HT250 cast iron structural parts. It is finished after secondary tempering to remove internal stress. It has good dynamic and static rigidity and no deformation. Precision numerical control indexing plate, servo drive 360° arbitrary indexing positioning and air/hydraulic locking, the drive system uses AC servo motor to automatically index the rotating shaft part 360°, and the indexing accuracy is one-thousandth of a degree. The indexing plate is placed on the top of the bed, and adjustable bolts are distributed on the bottom of the bed, which can easily adjust the level of the bed worktable.

2.2. Movable column: The movable cast iron structure column is finished after secondary tempering treatment to remove internal stress. It has good dynamic and static rigidity and no deformation. A set of precision ball screw pair and a servo motor make the column slide move in the Y-axis direction. A set of precision ball screw pair and a servo motor make the column slide move in the X-axis direction. Install a drilling unit on the unit slide. The movement of the column is realized by the rotation of the ball nut on the ball screw driven by the servo motor through the coupling.

2.3. Mobile saddle: The mobile saddle is equipped with two ultra-high bearing capacity rolling linear guide rail pairs, a set of precision ball screw pair and a servo motor, which drives the drilling power head to move in the Z-axis direction, which can realize Power head fast forward, work forward, fast reverse, stop and other actions. It has the functions of automatic chip breaking, chip removal and pause.

2.4. Drilling power head: The drilling power head adopts Taiwan mechanical spindle, and the special precision spindle adopts angular contact bearing, which realizes stepless speed change through high-strength synchronous belt transmission. Driven by servo motors and ball screws. The Y-axis can be linked, adopts semi-closed-loop control, and can realize linear and circular interpolation functions. The spindle end is a BT50 taper hole.

2.5. Automatic lubrication device and protection device:

This Machine is equipped with an automatic lubrication device, which can automatically lubricate the moving pairs such as guide rails, lead screws, and racks. Machine

The Z-axis and Y-axis are equipped with dust-proof protective covers, and waterproof splash baffles are installed around the worktable.

2.6. Full digital numerical control system:

2.6.1. With chip breaking function, chip breaking time and chip breaking cycle can be set on the man-machine interface.

2.6.2. Equipped with the tool lifting function, the tool lifting height can be set on the man-machine interface. When drilling reaches this height, the drill bit is quickly lifted to the top of the workpiece, then the chips are thrown away, and then fast forwarded to the drilling surface and automatically converted to working.

2.6.3. Centralized operation control box and hand-held unit adopt numerical control system and are equipped with USB interface and LCD liquid crystal display screen. In order to facilitate programming, storage, display and communication, the operation interface has functions such as man-machine dialogue, error compensation, and automatic alarm.

2.6.4. The equipment has the function of previewing and re-inspecting the hole position before processing, and the operation is very convenient

* In order to ensure the convenience of hoisting and feeding large rings, the Machine has no external protection, and external protection is optional.

3. Machine use environment:

Power supply: Three-phase AC380V±10%, 50Hz±1 Ambient temperature: 0°~ 45°

4.Technical parameters

|

Model |

BOSM-1000 |

|

|

Maximum processing workpiece size |

Allowable maximum rotation diameter of the workpiece (mm) |

≤Φ2000 |

|

Worktable |

Dimensions of worktable (mm) square |

□1000 |

|

Dimensions of worktable (mm) round |

Φ1200 |

|

|

Horizontal maximum load (kg) |

5000 |

|

|

Vertical Ram Drilling Unit |

amount) |

1 |

|

Spindle taper |

BT50 |

|

|

Drilling diameter (mm) |

2-120 |

|

|

Milling cutter disc diameter (mm) |

200 |

|

|

Tapping diameter (mm) |

M6-M36 |

|

|

Distance from spindle end face to table center (mm) |

1000-1600 |

|

|

Distance from the spindle center to the upper plane of the table (mm) |

100-1100 |

|

|

Spindle speed (r/min) |

30-3000 |

|

|

Spindle motor power (kw) |

30 |

|

|

Workpiece rotation axis (A axis) |

Maximum division number (mm) |

360° |

|

Set the minimum division unit |

0.001° |

|

|

A-axis servo motor power (kw) |

4.2 |

|

|

The power head moves left and right (X axis) |

Maximum stroke (mm) |

2000 |

|

X-axis moving speed (m/min) |

0~8 |

|

|

X-axis servo motor power (kw) |

2.4 |

|

|

The power head moves up and down (Y axis) |

Maximum stroke (mm) |

1000 |

|

Y-axis moving speed (m/min) |

0~8 |

|

|

Y-axis servo motor power (kw) |

2.4 Brake |

|

|

Column longitudinal movement (Z axis) |

Maximum stroke (mm) |

600 |

|

Z-axis moving speed (m/min) |

0~4 |

|

|

Z axis servo motor power (kw) |

2.4 |

|

|

Positioning accuracy |

1000mm |

±0.05 |

|

Repeatability |

1000mm |

±0.025 |

|

CNC indexing table indexing accuracy (mm) |

|

15” |

|

Machine dimensions (including protection) |

Length (X) × Width (Z) × Height (Y) (mm) |

约 5300*6000*3400 |

|

Gross weight (t)including protection |

(about)20 |

|