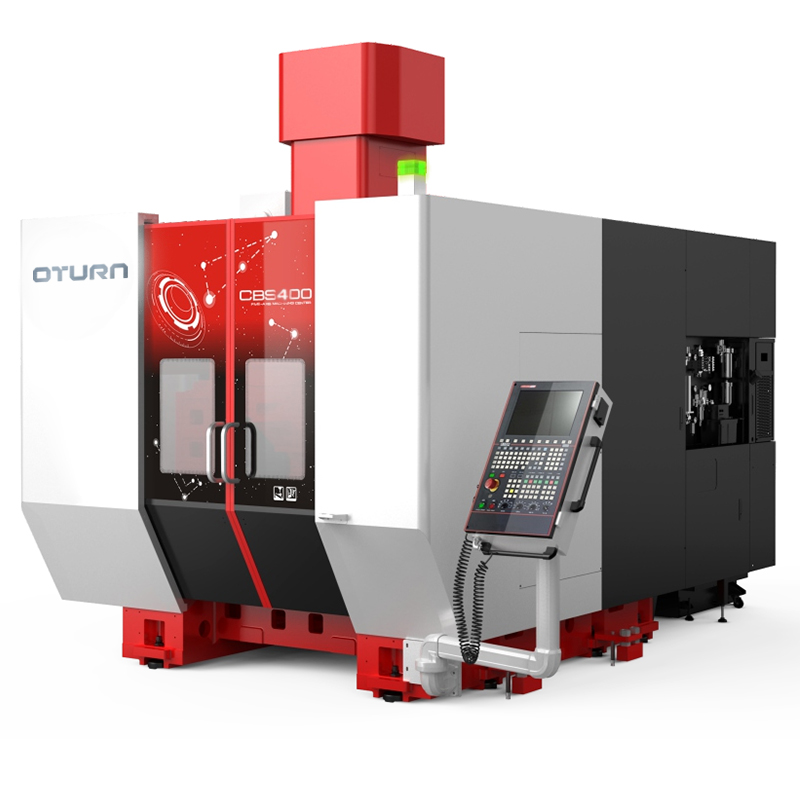

5-axis Bridge Machining CenterCBS400

1.Overview

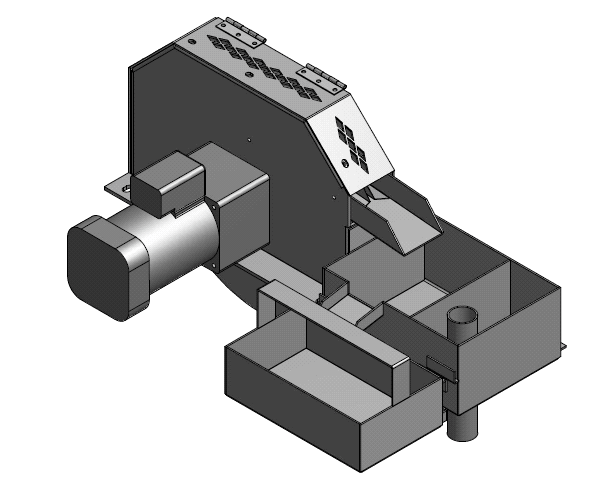

The high-speed precision bridge-type five-axis machining center CBS400 has the characteristics of high rigidity, high precision and high-efficiency machining. CBS series machine tools adopt bridge structure layout, XYZ axis movement is not affected by AC axis, and can maintain high-precision machining for a long time; X/Y/Z/A/C axes are fully closed-loop controlled to ensure high-precision machining; the whole machine adopts finite element analysis The individual components are designed to provide the best overall stable performance.

The three-axis rapid displacement is 30 M/min, the T-T tool change time is only 4S, the tool magazine is fully loaded for 24 hours, and there is no alarm for tool change . It is suitable for two or three-dimensional concave-convex models with complex shapes that require 5-axis linkage for one-time processing. It is more suitable for small and medium-sized batches of multi-variety processing and production, and can also enter automatic lines for mass production.

Using HEIDENHAIN's latest TNC640 system, 15-inch large LCD display, smart warning display, self-diagnosis and other functions make the use and maintenance of the machine tool more convenient and fast; multi-segment pre-reading control is especially suitable for mold processing with high-speed and large-capacity programs. Supports network and USB program transmission, which facilitates fast and efficient transmission and online processing of large-capacity programs.

2.Parameter

|

Item |

Unit |

spec |

|

|

travel |

X/Y/Z axis travel |

mm |

460×390×400 |

|

Distance from spindle end face to worktable surface |

mm |

155-555 |

|

|

The maximum distance between the spindle center and the table surface when the A axis is 90° |

mm |

315 |

|

|

Maximum processing range |

mm |

φ400*400 |

|

|

C-axis turntable

|

Disk diameter |

mm |

Φ400 |

|

Turntable T-slot/guide key width |

mm |

14H7/25H7 |

|

|

allowable load |

kg |

400 |

|

|

Three-axis feed |

X/Y/Z axis rapid displacement |

m/min |

30/30/30 |

|

Cutting feed rate |

mm/min |

1-12000 |

|

|

spindle |

Spindle specifications (installation diameter/transmission mode) |

mm |

120/built in |

|

Spindle taper |

mm |

E40 |

|

|

Spindle speed |

r/min |

30000 |

|

|

Spindle Motor Power (Continuous/S3 40%) |

kW |

11/13.2 |

|

|

Spindle Motor Torque (Continuous/S3 40%) |

N.m |

11.5/13.8 |

|

|

Tool magazine |

Magazine capacity |

|

26 |

|

Tool change time (T-T) |

s |

5 |

|

|

tool diameter |

mm |

80 |

|

|

tool length |

Mm |

200 |

|

|

tool weight |

kg |

3 |

|

|

guide |

X-axis guideway (size/number of sliders) |

mm |

35/2 |

|

Y-axis guideway (dimensions/quantity of sliders) |

45/2 |

||

|

Z-axis guideway (dimensions/quantity of sliders) |

35/2 |

||

|

Three-axis drive |

X-axis screw |

|

Φ40×10 |

|

Y-axis lead screw |

|

Φ40×10 |

|

|

Z axis screw |

|

Φ40×10 |

|

|

5-axis |

A-axis rated/maximum speed |

rpm |

30/60 |

|

A-axis rated/maximum cutting torque |

Nm |

940/2000 |

|

|

C-axis rated/maximum speed |

rpm |

100/150 |

|

|

C-axis rated/maximum cutting torque |

Nm |

185/318 |

|

|

A-axis positioning/repeatability |

arc-sec |

10/6 |

|

|

C-axis positioning/repeatability |

arc-sec |

8/4 |

|

|

Three-axis accuracy

|

positioning accuracy |

mm |

0.005/300 |

|

Repeatability |

mm |

0.003/300 |

|

|

lubrication system

|

Lubrication unit capacity |

L |

0.7 |

|

Lubrication type |

|

grease lubrication |

|

|

cutting fluid

|

tank capacity |

L |

300 |

|

Cutting pump parameters |

|

0.32Mpa×16L/min |

|

|

other |

air demand |

kg/c㎡ |

≥6 |

|

Air source flow |

mm3/min |

≥0.5 |

|

|

battery capacity |

KVA |

30 |

|

|

Machine Weight (Comprehensive) |

t |

5 |

|

|

Host Dimensions (L×W×H) |

mm |

3360×2910×2850 |

|

3.Standard configuration

| No. | Item |

| 1 | Heidenhain TNC640 operating system (five-axis linkage)

①Smooth jerk motion control; ②Automatic follow-up function of tool tip; ③ Coordinate transformation; ④ Tool 3D compensation; ⑤ USB and Ethernet data transmission. |

| 2 | Simultaneous tapping function |

| 3 | Spindle temperature control system |

| 4 | Spindle overload protection |

| 5 | Fully enclosed sheet metal |

| 6 | security door lock system |

| 7 | Tool magazine automatic door |

| 8 | Automatic grease lubrication system |

| 9 | LED work lighting |

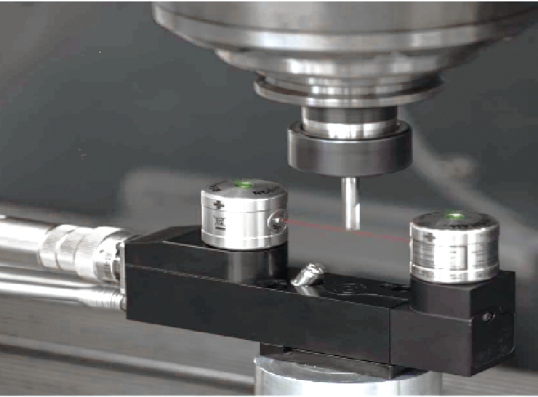

| 10 | Mechanical tool setting device |

| 11 | Lifting Chip Conveyor System |

| 12 | Electric cabinet air conditioner |

| 13 | cleaning air gun |

| 14 | Process blowing system |

| 15 | Surround sprinkler system |

| 16 | coolant system |

| 17 | Standard tools and tool boxes |

4.Parts Specifications

| No. | name | spec | Brand /origin |

| 1 | body | CBS400 | CATO |

| 2 | system | TNC640 | Heidenhain |

| 3 | Three-axis guide rail | 35/45/35 | HIWIN/PMI |

| 4 | Three-axis screw | φ40*10 | HIWIN/PMI |

| 5 | X/Y/Z motor | QSY155C/QSY155F*2 | Heidenhain |

| 6 | Spindle | E40-M120-30000rpm | CATO |

| 7 | Servo tool magazine | 26T | CATO |

| 8 | lubrication system | PJB-20607T(脂润滑) | river valley |

| 9 | Airway components | CBS400 | SMC/Festo |

| 10 | AC contactor/thermal overload/circuit breaker | CBS400 | Schneider/Honeywell |

| 11 | LED work lights | YT-14 AC/DC24V | Olden |

| 12 | Three-color light | 301A0LL | CATO |

| 13 | Nozzle cutting fluid supply device | CBS400 | CATO |

| 14 | hair dryer | CBS400 | CATO |

| 15 | Tool setting instrument | TM26D | Metrol |

| 16 | Water cooler | Quanguan/same level | |

| 17 | Surround sprinkler system | CBS400 | CATO |