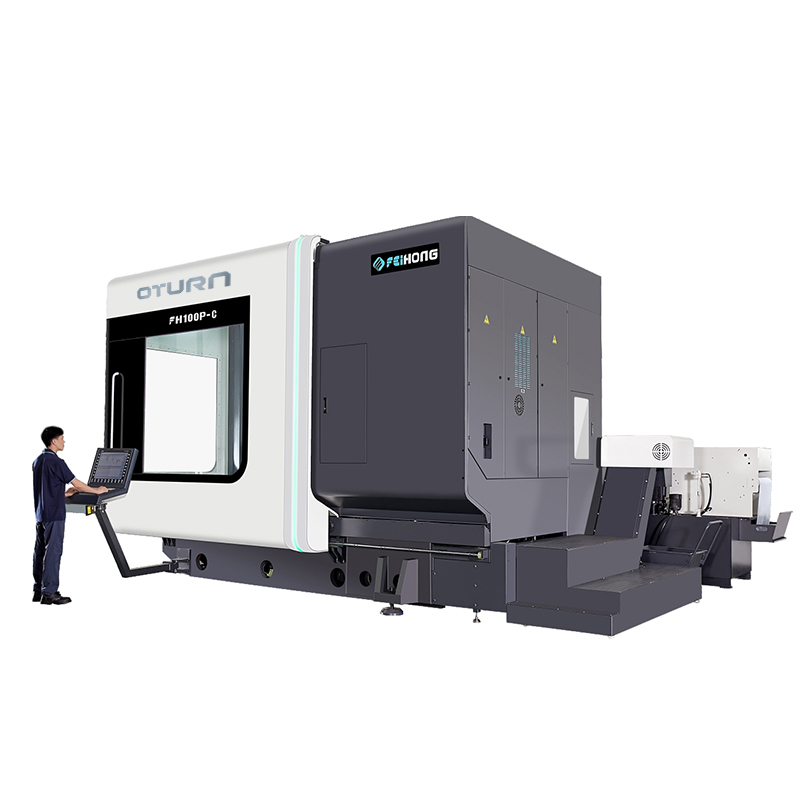

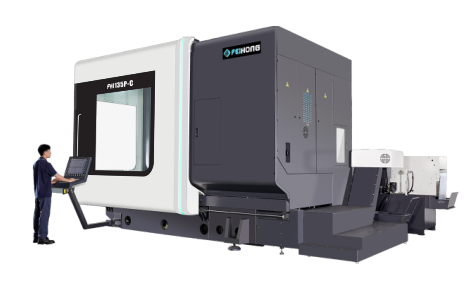

5 Axes Simultaneous Milling Turning 135P-C

Scope of supply

Standard accessories function table (please refer to the controller function for the electric control part)

| No | Item | Unit | Qty |

| 1. | FH mainframe castings | tower | 1 |

| 2. | Siemens840DSL control system | set | 1 |

| 3. | Display: 19LCD | set | 1 |

| 4. | FH five-axis multi-function swing head (B-axis) | set | 1 |

| 5. | DGZX-28010/25-KFHWVJS | piece | 1 |

| 6. | X/Y/Z Axis Hollow Cooled Ball Screws | piece | 3 |

| 7. | Mill/Turn Direct Drive Rotary Table (C-axis) | set | 1 |

| 8. | B axis RCN8380 29 bits absolute encoder | piece | 1 |

| 9. | C axis RCN2580 28 bits absolute encoder | piece | 1 |

| 10. | BOSCH REXROTH Roller Linear Slides | set | 7 |

| 11. | Electrical box temperature control device | set | 1 |

| 12. | Spindle water cooling system | set | 1 |

| 13. | Machine tool ring water spray | set | 1 |

| 14. | Five-axis head crescent water spray, crescent blowing | set | 1 |

| 15. | Front and side working door safety interlock system | set | 1 |

| 16. | Waterproof work bin lighting | piece | 2 |

| 17. | hydraulic station | set | 1 |

| 18. | Central centralized feed lubrication device | set | 1 |

| 19. | Operation side cleaning water gun and air gun | set | 1 |

| 20. | Cutting fluid system | set | 1 |

| 21. | Fully enclosed protective sheet metal | set | 1 |

| 22. | Operation box | set | 1 |

| 23. | Electrical Cabinet Cooling Unit | set | 1 |

| 24. | Siemens electronic handwheel | piece | 1 |

| 25. | Foot-operated spindle knife release switch | piece | 1 |

| 26. | Machine tool tri-color light | set | 1 |

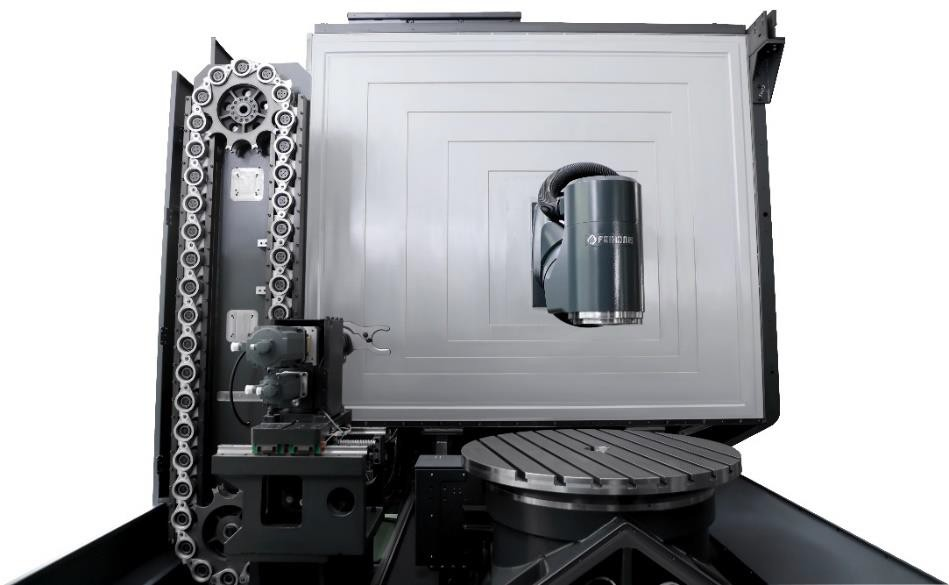

| 27. | 40 HSK-A63 tool magazines and servo automatic tool changing system | set | 1 |

| 28. | X/Y/Z three-axis absolute value grating scale | set | 3 |

| 29. | Spiral Chip Roller and Rear Chip Conveyor Chip Carriage | set | 1 |

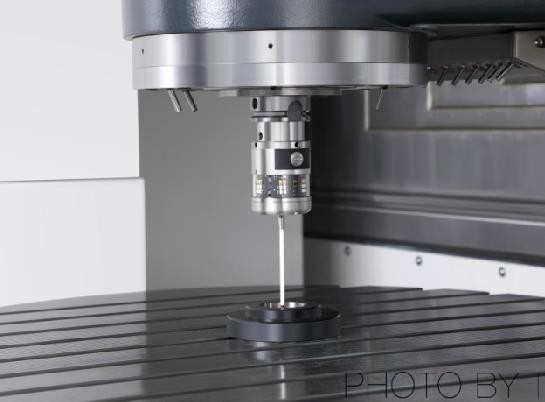

| 30. | Hexagon IRP25.50 Infrared Probe Unit | set | 1 |

| 31. | Renishaw NC4F230 tool setter unit | set | 1 |

| 32. | Foundation level pads and foundation bolts | set | 1 |

| 33. | technical manual | set | 1 |

Parameter

|

Model |

Unit |

FH135P-C |

|

Travel |

||

|

X axis travel |

mm |

1450 |

|

Y axis travel |

mm |

1350 |

|

Z axis travel |

mm |

1100 |

|

Distance from spindle nose to work table surface |

mm |

160-1260 |

|

Horizontal milling head |

mm |

30-1130 |

|

Feed/fast moving speed |

m/min |

40 |

|

Feed force |

KN |

10 |

|

Rotary table (C axis) |

||

|

Working table size |

mm |

Ø1350 |

|

Max.table load (mill) |

kg |

4000 |

|

Max.table load (turning) |

kg |

3000 |

|

Milling/turning table (milling and turning combined machining) |

rpm |

250 |

|

Minimum split angle |

° |

0.001 |

|

Rated torque |

Nm |

1330 |

|

maximum torque |

Nm |

2630 |

|

CNC swing milling head (B axis) |

||

|

Swing range (0=vertical/180=horizontal) |

° |

-15~180 |

|

Rapid traverse and feed rate |

rpm |

50 |

|

Minimum split angle |

° |

0.001 |

|

Rated torque |

Nm |

1050 |

|

maximum torque |

Nm |

2130 |

|

Spindle (milling and turning) |

||

|

Spindle speed |

rpm |

10000 |

|

Spindle power |

Kw |

25/37.5 |

|

Spindle torque |

Nm |

200/300 |

|

Spindle tapre |

|

HSKA100 |

|

Tool magazine |

||

|

Tool interface |

|

HSKA100 |

|

Tool magazine capacity |

PCS |

40 |

|

Maximum tool diameter/length/weight |

|

Ø135/300/12 |

|

Tool change time (tool to tool) |

S |

2 |

|

Measuring device |

||

|

Infrared probe |

Hexagon IRP25.50 Infrared Probe Unit | |

|

Tool detection instrument in working processing area |

Renishaw NC4F230 tool setter unit | |

|

Position accuracy (ISO230-2 and VDI3441) |

||

|

X/Y/Z positioning accuracy |

mm |

0.008 |

|

X/Y/Z Repeat positioning accuracy |

mm |

0.005 |

|

B/C positioning accuracy |

|

10" |

|

B/C Repeat positioning accuracy |

|

4" |

|

CNC controller |

||

|

CNC system |

|

Siemens840D |

Design Features | Best Mechanical Wire Casting Analysis Design

◆Full box-type thermosymmetric casting structure, using Meehanna grade high-grade cast iron

◆Tempering and natural aging treatment to eliminate internal stress

◆Structural natural frequency vibration eliminates material processing stress

◆Comprehensive wall and large-area high-rigidity column design can effectively improve rigidity and static and dynamic accuracy

◆Three-axis hollow cooling screw drive

Electric Spindle

Design Features

◆According to the characteristics of their own machines, independent research and development and production.

◆The taper hole of HSK-A100 is adopted in the FH135P-C model.

◆Adopt external cooling system for circulating cooling, which can effectively ensure the application of electric spindle.

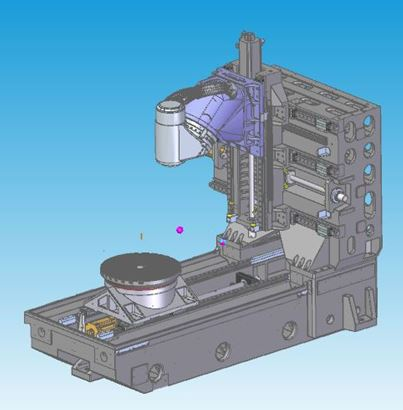

3.3 CNC swing milling head (B axis)

Design Features

Design Features

◆Independent design and production.

◆Built-in DD motor zero transmission chain no backlash design.

◆High acceleration characteristics.

◆The shortest span between the tool nose point of the spindle and the structural support point realizes the maximum rigidity of cutting.

◆Larger YRT bearing improves rigidity.

◆ Equipped with HEIDENHAIN RCN8380 series absolute rotary encoder measurement system, fully closed-loop control, to ensure the best accuracy.

◆B-axis cooling system design reduces heat transfer.

3.4 Rotary table (C-axis table)

Design Features

◆Independent design and production.

◆Built-in DD motor zero transmission chain no backlash design.

◆High acceleration and deceleration response characteristics.

◆Larger YRT bearing increases rigidity.

◆Large rated driving torque, positioning and processing with table positioning and clamping device

◆Meet the needs of milling, reduce workpiece handling and improve product accuracy.

◆Equipped with HEIDENHAIN high-precision rotary encoder measurement system, fully closed-loop control to ensure the best accuracy.

◆Cooling system design to reduce heat transfer.

3.5 Control system

Selection features

◆Select the control host NCU730.3B for five-axis linkage (see the function table for details of the system configuration)

◆With RTCP function

◆Choose Siemens S120 drive with 3 times overload capacity and 1FT series motor with high kinematic characteristics

◆Select TCU30.3+ICP427E as HMI interactive host, IPC has higher computing speed and higher storage space

3.6 Automatic tool changing system

Design Features

◆ Independent design and production.

◆Tool selection and tool change use servo motor to control the terminal action, which is more stable and accurate.

◆Combined with the tool management function of Siemens840DSL, more efficient tool management.

3.7 Liftable tool setter

Design Features

◆Equipped with Ransishaw NC4F230R tool setter with higher precision.

◆Automatic tool setting on the machine, automatic update of tool compensation.

◆The tool setting device can be raised and lowered to save the space of the processing surface.

◆Fully sealed sheet metal design to protect the tool setter from damage by water and iron filings during processing.

3.8 Infrared probe

Design Features

◆Equipped with Hexagon IRP25.50 Infrared Probe Unit.

◆On-machine workpiece alignment and size inspection can reduce manual inspection errors and improve product accuracy and processing efficiency.

◆90% savings in on-board assistance time.