We are at your service with timely

We provide one-stop access to top Chinese machine tool suppliers, backed by professional overseas service teams and strict project protection. Enjoy comprehensive support, flexible payment terms, and open communication for better market opportunities.

We can help you choose screen printing machines with different functions and configurations, combined with UV curing machines, paper stackers and other auxiliary equipment to constitute a complete set of printing lines playing an undeniably positive role in the factory’s efficiency and cost performance.

- Aviation & Aerospace

- Traditional & Electric Car Industry

- Construction & Ships Industry

- Mould & Metal Industry

- Oil & Petroleum Industry

-

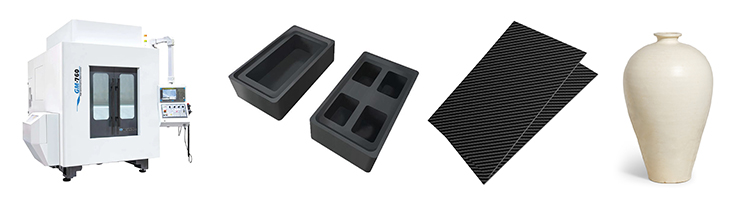

CNC machining center for graphite, carbon fiber and ceramics

This CNC machine features a compact, stable, and high-strength enclosed structure, with the bed and column forming a closed, integrated unit. This effectively reduces machine vibration and improves machining stability and precision. The tool magazine is compact yet large, holding up to 32 tools when using an HSK-E40 spindle. Its modular design makes the machine suitable for automated production lines and is particularly well-suited for specialized CNC machining of materials such as graphite, carbon fiber, and ceramics, meeting the demands of high precision and efficiency.

This CNC machine features a compact, stable, and high-strength enclosed structure, with the bed and column forming a closed, integrated unit. This effectively reduces machine vibration and improves machining stability and precision. The tool magazine is compact yet large, holding up to 32 tools when using an HSK-E40 spindle. Its modular design makes the machine suitable for automated production lines and is particularly well-suited for specialized CNC machining of materials such as graphite, carbon fiber, and ceramics, meeting the demands of high precision and efficiency. -

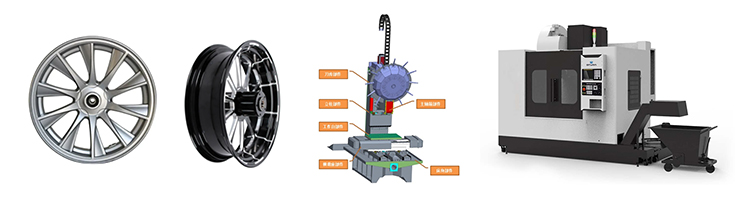

Wheel hub CNC machining center

This CNC machine is suitable for machining motorcycle wheels up to 19 inches. It utilizes high-strength resin sand casting to create a stable C-shaped structure, ensuring both rigidity and stability. The worktable measures 600 x 360 mm and has a load capacity of 200 kg. Equipped with a spindle with a maximum speed of 8000 RPM and a rapid tool change system, it boasts a tool magazine capacity of 12 tools and a tool change time of just 3s, improving machining efficiency. Its high-precision positioning and fully enclosed protective design make it ideal for machining motorcycle wheels and similar complex parts.

This CNC machine is suitable for machining motorcycle wheels up to 19 inches. It utilizes high-strength resin sand casting to create a stable C-shaped structure, ensuring both rigidity and stability. The worktable measures 600 x 360 mm and has a load capacity of 200 kg. Equipped with a spindle with a maximum speed of 8000 RPM and a rapid tool change system, it boasts a tool magazine capacity of 12 tools and a tool change time of just 3s, improving machining efficiency. Its high-precision positioning and fully enclosed protective design make it ideal for machining motorcycle wheels and similar complex parts. -

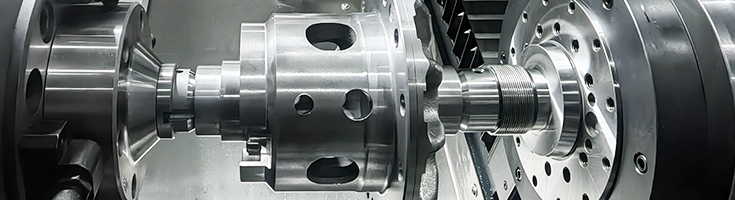

Differential shell application case

The product being processed must meet requirements for both ends, with outer diameter and roundness controlled within 0.005mm, taper within 0.002mm, and inner and outer coaxiality within 0.015mm. Data is measured using a three-dimensional coordinate measuring machine (CMM). Through a customized reinforced tailstock and special guideways, combined with precise installation and adjustment, the spindle coaxiality and contour accuracy are controlled within 0.002mm, ensuring high stability and precision of the machined parts.

The product being processed must meet requirements for both ends, with outer diameter and roundness controlled within 0.005mm, taper within 0.002mm, and inner and outer coaxiality within 0.015mm. Data is measured using a three-dimensional coordinate measuring machine (CMM). Through a customized reinforced tailstock and special guideways, combined with precise installation and adjustment, the spindle coaxiality and contour accuracy are controlled within 0.002mm, ensuring high stability and precision of the machined parts. -

Aluminum alloy application cases

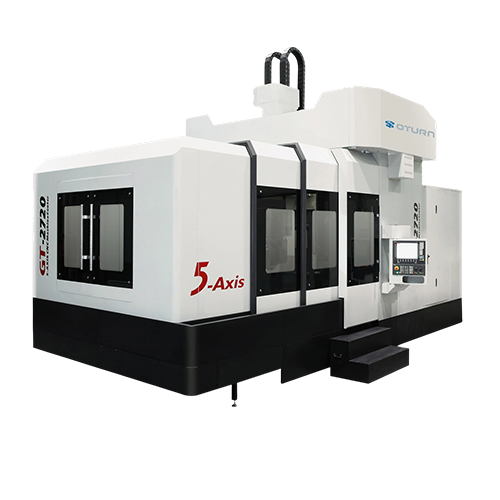

This product is made of aluminum alloy and has a maximum overall size of 1520 x 1000 mm. It primarily processes precision milling, drilling, boring, and complex surface machining of discs, sleeves, and plates. This workpiece is suitable for use on a GT series vertical machining center equipped with a highly rigid BBT40 direct-coupled mechanical spindle capable of reaching a maximum speed of 12,000 RPM, ensuring efficient and stable cutting performance. The machine is equipped with high-precision three-axis roller screw guides and an intelligent tool magazine system, supporting multiple steps in a single clamping process, significantly improving processing efficiency and quality.

This product is made of aluminum alloy and has a maximum overall size of 1520 x 1000 mm. It primarily processes precision milling, drilling, boring, and complex surface machining of discs, sleeves, and plates. This workpiece is suitable for use on a GT series vertical machining center equipped with a highly rigid BBT40 direct-coupled mechanical spindle capable of reaching a maximum speed of 12,000 RPM, ensuring efficient and stable cutting performance. The machine is equipped with high-precision three-axis roller screw guides and an intelligent tool magazine system, supporting multiple steps in a single clamping process, significantly improving processing efficiency and quality.

Send your message to us:

Write your message here and send it to us